Dairy Foods & Beverages

Varieties include coffee with grass-fed organic half & half, and coffee with grass-fed organic chocolate milk

Read More

La Colombe Coffee Roasters adds three varieties to its RTD coffee/draft latte line

The two new latte flavors are honeysuckle and Brazilian caramel.

May 15, 2018

Bolthouse Farms introduces reduced-sugar refrigerated protein beverages

The line includes protein beverages made with whey protein concentrate and non-dairy beverage smoothies.

May 11, 2018

Vermont Creamery adds three fresh flavored goat cheeses

The goat cheeses are sold in in 4-ounce chèvre logs.

May 10, 2018

Praline's Inc. is a champion of quality ice cream

Praline’s Inc. crafts its award-winning ice cream using high-quality ingredients — many of them made from scratch — and an impressive hand-mixing technique

May 9, 2018

Ice cream

Successfully flavor ice cream in a cost-competitive environment

The management of flavor-related costs also requires a focus on elements that influence body, texture, sweetness and other factors.

May 9, 2018

Teach and tell to market cheese successfully

Storytelling and education are important when it comes to connecting consumers with cheese.

May 8, 2018

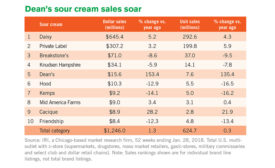

Cultured dairy sales see downswing

Sales of refrigerated yogurt, cottage cheese and kefir slide. Meanwhile, cream cheese and sour cream fare better, and shelf-stable yogurt/yogurt drinks take off.

May 8, 2018

Applegate Farms launches a natural cheese line

The cheese is available in six sliced varieties, including medium cheddar, American-style Colby and mozzarella.

May 7, 2018

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing