A look inside HP Hood's Sacramento plant

HP Hood fills 600 bottles a minute on its new aseptic line in its Sacramento, Calif., plant. The company processes dairy and nondairy beverages in aseptic and extended shelf life packages.

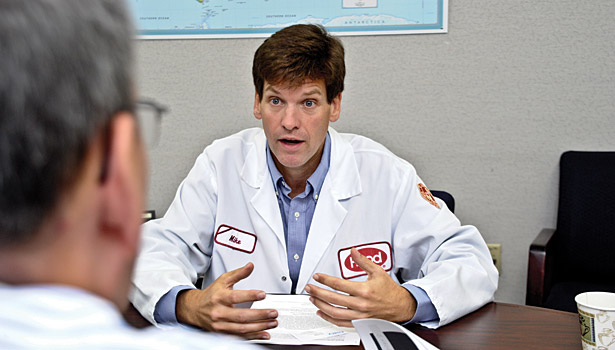

Mike Hardy is showing me an aseptic filler. “There are only two speeds to this — 0 and 600 bottles a minute,” he says. I watch a blur of bottles enter one end of the machine from an overhead conveyor, whirl from carousel to carousel and exit the other end. In a matter of seconds, the bottles have been sterilized, filled and capped.

Hardy is the director of operations of HP Hood’s Sacramento, Calif., dairy plant. Hood finished installing the aseptic filler in 2012. The facility processes ultra-high-temperature (UHT) dairy and nondairy beverages (including milk, cream and almond milk) in extended shelf life packages and aseptic packages.

According to the Food and Drug Administration, high-temperature short-time pasteurization “is important to the dairy industry because of the operating efficiencies that it affords. Properly operated, these units allow a high volume of production in a minimum of processing space.”

UHT processing heats raw milk to 280 degrees F (and higher) for two seconds. (The milk doesn’t boil because it is heated in a vacuum.) Manufacturing ESL and aseptic beverages gives processors distinct advantages. For one, the processing plant does not have to be located near population centers. It can be close to the milk source. For another, the longer shelf life extends the territory that a processor can service. ESL products stay fresh from 60 to 120 days (two to four times longer than conventionally processed milk) before reaching their expiration date. Aseptic packages have an even longer life — a year or more — and they don’t need to be refrigerated. That’s a boon for small retailers who lack cooling capabilities for back stock.

In the case of Hood, having ESL capabilities on the West Coast allows the East Coast-based dairy processor to better respond to the needs of national customers and to meet the growing demand for shelf-stable nondairy products like nutritional drinks, said Mike Newell, director of business development. Two other Hood plants (in Winchester, Va., and Oneida, N.Y.) also have aseptic packaging capabilities.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!