Home » Publications » Dairy Foods eMagazine

Dairy Foods eMagazine

2012 April

Cover Story

Back to TopFoods & Beverages

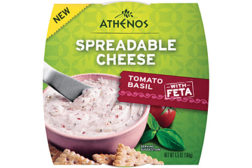

Back to TopCheese Sales Rise 7%, No Matter How You Slice It

Sales in the natural cheese category were up 7% last year, with shredded cheese outpacing the industry. But overall, unit sales were weak.

April 10, 2012

Processors

Back to TopTillamook has been making quality dairy foods for more than 100 years

Start with high-quality milk and develop dairy foods in a responsible manner.

April 10, 2012

Ingredients

Back to TopDairy processors seek alternatives to sugar to sweeten dairy foods

Americans want to cut back on sugar intake. Dairy product formulators can choose from an array of nutritive and non-nutritive sweeteners, some of which contribute flavor, color and nutrients.

April 10, 2012

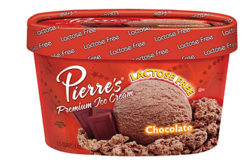

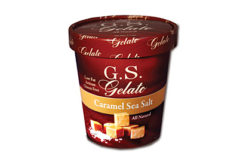

Dealing With the Wild Swings of Stabilizer Prices

Now is a good time to take a new look at low-viscosity polysaccharides such as gum acacia to stabilize ice cream.

April 12, 2012

Dairy Foods and Demographics: Dairy Foods for All Ages

Infants, adolescents, adults and seniors have specific nutritional needs. Milk serves as a base for functional ingredients that can deliver those nutrients.

April 10, 2012

Operations

Back to TopWater management practices in dairy processing plants

The best fluid-milk plants use about one-half gallon of water per gallon of milk processed. The least efficient plants use four times that amount.

April 10, 2012

Prepare Your Plant to Comply with Food Safety Act

Look for some regulations contained in the Food Safety Modernization Act to be released as early as this summer, with more to come by year’s end and into 2013.

April 10, 2012

Designing Sustainable Packages for Dairy Foods

Take a holistic and collaborative approach to packaging design. This approach is about leveraging all of the design-related components early in the new product idea process.

April 10, 2012

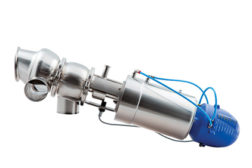

Best practices for pumps and valves in dairy processing plants

Choosing the right pump and the right valve can make a dairy plant more efficient. Properly sized equipment leaves little waste in the pipeline and gets the most from CIP solutions.

April 10, 2012

Time to get ready for FSMA

The Food Safety Modernization Act became law in 2011. The FDA is now writing proposed regulations that will likely take effect next year. What do dairy companies need to do to get ready?

April 10, 2012

Suppliers

Back to TopStay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing