Home » Keywords: » Extended Shelf Life

Items Tagged with 'Extended Shelf Life'

ARTICLES

Aseptic and ESL growing in importance

Extended shelf life and aseptic processes are becoming increasingly popular as dairy processors seek to keep pace in an increasingly competitive market.

December 4, 2023

The dairy packaging sector feels the heat

Aseptic and retort packaging are becoming more popular and potent forces in the war against pathogens.

December 3, 2021

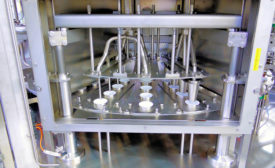

ESL, aseptic processing suppliers extend shelf life

New innovations in ESL and aseptic processing are allowing processors to meet consumer demand for complex formulations and longer shelf lives

December 18, 2019

ESL technology delivers more ways to add value to milk

Investing in technology that extends shelf life by even only five days can have a positive impact on the bottom line.

March 13, 2018

ESL processing expands a dairy’s revenue stream

Dairy brands looking to capitalize on consumers’ desire for nutritious, portion-packed milk can do so by investing in extended-shelf life technology.

April 13, 2017

Byrne Dairy extends its reach with ESL fluid milk products

The benefits of extended shelf life processing include opportunities in product innovation and extending the distribution area for dairy products.

April 11, 2017

Extend your reach with ESL products

The advantages of manufacturing extended shelf life milks include increased plant efficiency, reduced distribution costs and reduced product returns.

April 15, 2016

EVENTS

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing