Home » Keywords: » heat exchangers

Items Tagged with 'heat exchangers'

ARTICLES

SPX Flow introduces new heat exchanger

The Origin Series SSHE is engineered for multi-use performance and global applications

January 4, 2024

The future is bright for heat exchangers

Technology developers are launching designs that are enabling dairy processors to cut expenses while enhancing food quality.

August 8, 2023

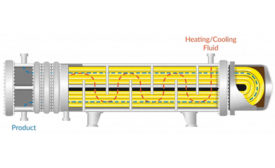

Heat exchangers add pizzaz to processing operations

State-of-the art heat transfer technologies are enhancing functionality and making equipment selection increasingly important.

October 20, 2022

Heat exchangers offer big processing paybacks

Selecting the proper heat exchanger and keeping the system operating efficiently can be challenging but fruitful.

September 29, 2021

Case Study

Cheese processor uses heat exchangers to increase cheese-drying capacity

HRS Heat Exchangers' evaporation technology helped expand production volume.

February 16, 2021

A hot market for heat exchangers in dairy processing

Upgrades to technologies are enabling dairy processors to produce higher quality products more efficiently and cost-effectively.

October 13, 2020

Regular maintenance keeps heat exchangers running

Dairy processors could avoid costly downtime with regular and long-term maintenance plans for their heat exchangers

October 23, 2019

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing