Packaging Technologies-Dairy Processors

Demand increases for renewable content and recycled content for milk cartons, yogurt cups and other dairy foods and beverages.

Read More

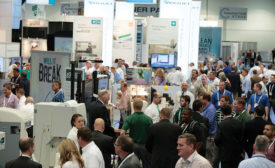

Sustainability, product safety are top issues at 2017 Pack Expo

The 2017 Pack Expo gives dairy processors information on the latest packaging and processing trends and innovations.

September 11, 2017

Flexible packaging boosts sales

Consumers like packaging that is easy to open and reseal.

August 7, 2017

Cold medals

In-mold labels lick ice cream problems

Froneri Brazil uses an injection-molded cup and a reclosable polypropylene lid. New Orleans Famous Sno-Balls to Go chooses an IML package for better print quality.

July 10, 2017

Packaging equipment

PFM Packaging Machinery launches high-speed stand-up pouch machine

The stand-up pouch machine can produce up to 480 pouches per minute.

July 7, 2017

Shelf life and shelf impact drive dairy packaging

Two other factors garnering attention from brand marketers are convenience and sustainability. Here’s a look at innovative packaging, including aseptic containers and in-mold labels.

June 8, 2017

4 questions to help improve labels, labeling performance

From sustainability demands and trends, to challenging processing environments, the choices manufacturers make with their labels can have a significant impact. Labeling suppliers discuss these topics and more.

May 15, 2017

Chemours the merrier

‘SPF’ for milk packages certifies that nutrients are protected

A logo signifies that the packaging has been audited for its ability to screen light.

April 5, 2017

Please sleeve

Sleeve packaging is the right solution for a Finnish yogurt maker

Juustoportti can output 200 4-packs products a minute thanks to a robotic solution by equipment maker Gerhard Schubert.

March 20, 2017

Dairy snacks need their own packaging

Milk, cheese, yogurt and cottage cheese are healthy alternatives to fried or baked snacks and candies. So these dairy snacks need to be packaged in single-serve or snack-size formats.

March 13, 2017

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing