Equipment

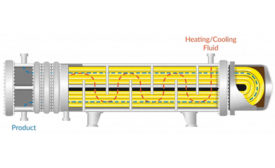

A hot market for heat exchangers in dairy processing

Upgrades to technologies are enabling dairy processors to produce higher quality products more efficiently and cost-effectively.

October 13, 2020

Conveyor, palletizer upgrades keep dairy processors on the fast track

Dairy processors are able to operate more powerfully and productively.

September 11, 2020

Case Study

Masters Gallery Foods facilitates high-speed cheese packaging with flexible robots

Quest Industrial’s robots help the cheese company package a large volume of diverse products.

August 25, 2020

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing