Dairy Processing and Equipment

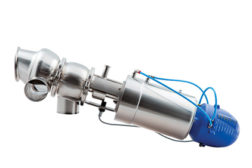

Best practices for pumps and valves in dairy processing plants

Choosing the right pump and the right valve can make a dairy plant more efficient. Properly sized equipment leaves little waste in the pipeline and gets the most from CIP solutions.

April 10, 2012

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing