Dairy Processing and Equipment

Sustainability

Unilever Ice Cream, Ballard Family Dairy & Cheese honored in dairy sustainability awards program

Unilever has reduced electricity use by 13%, natural gas use by 16% and water consumption by more than 1.1 million gallons per year.

April 24, 2013

Construction

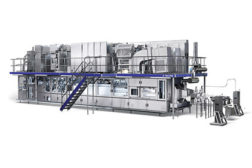

Darigold completes construction of plant dryer in Lynden, Wash.

Darigold exports two thirds of its milk powder production and three-quarters of its whey products.

April 20, 2013

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing