Home » aseptic

Articles Tagged with ''aseptic''

Ever-increasing demand, combined with unique properties of dairy products, is leading to widespread innovation.

Read More

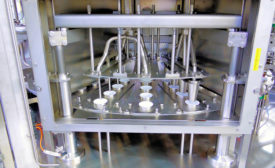

The importance of aseptic and ESL for dairy

Aseptic and ESL are indispensable packaging formats for dairy products.

December 27, 2024

HP Hood LLC named 2024 Dairy Foods Plant of the Year

Batavia, N.Y., facility honored for employee safety as well as operational excellence.

September 4, 2024

Opportunities abound in RTD beverages

Younger demographics are especially interested in this category.

January 24, 2024

Dairy Farmers of America is Dairy Foods 2023 Processor of the Year

DFA honored for operations, product innovation and sustainability.

December 15, 2023

Aseptic and ESL growing in importance

Extended shelf life and aseptic processes are becoming increasingly popular as dairy processors seek to keep pace in an increasingly competitive market.

December 4, 2023

SIG launches on-the-go carton bottle

Designed for recycling, SIG DomeMini is mainly made from FSC-certified paperboard and produced using 100% renewable electricity

October 16, 2023

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing