The latest about labeling, shrink sleeves and printing systems

Selecting the optimal items in this space can be challenging.

Photo courtesy of jxfzsy / iStock / Getty Images Plus.

Ongoing upgrades to labeling, shrink sleeve, and printing technologies are enabling dairy processors to enhance the aesthetic appeal of products while displaying more information.

Yet, leveraging the optimal equipment remains arduous. With a plethora of systems supporting a wide spectrum of packaging designs, operators must sort through a host of possibilities. That includes choosing from among dozens of paper or synthetic substrates for labeling, says Dan Mack, technical product manager for labeling at Multivac US, a Kansas City, Mo.-based manufacturer of labelling and packaging equipment.

Finding the ideal choice is a matter of considering such factors as the rigidity and shape of surface, and desired aesthetics, he states. Package contour also influences the label applicator configuration, Mack says, which can include attaching labels by blowing, pressing or rolling on.

Other variables include whether printing is occurring on a label, flexible plastic, coated paperboard, or other surface, and the desired speed for moving products through the printer, he states. The amount, size and detail of the print is important too as equipment can vary in accordance with such factors as whether printing involves a simple code date or a complete ingredient statement, Mack explains.

It also is essential to understand the storage and distribution plans for products, such as whether the items will sell at a retail outlet or remain in a warehouse before shipping to consumers, says Leslie Gurland, vice president of sales and marketing at Premium Label & Packaging Solutions, a Fairfield, N.J.-based supplier of labels, shrink sleeves and flexible packaging.

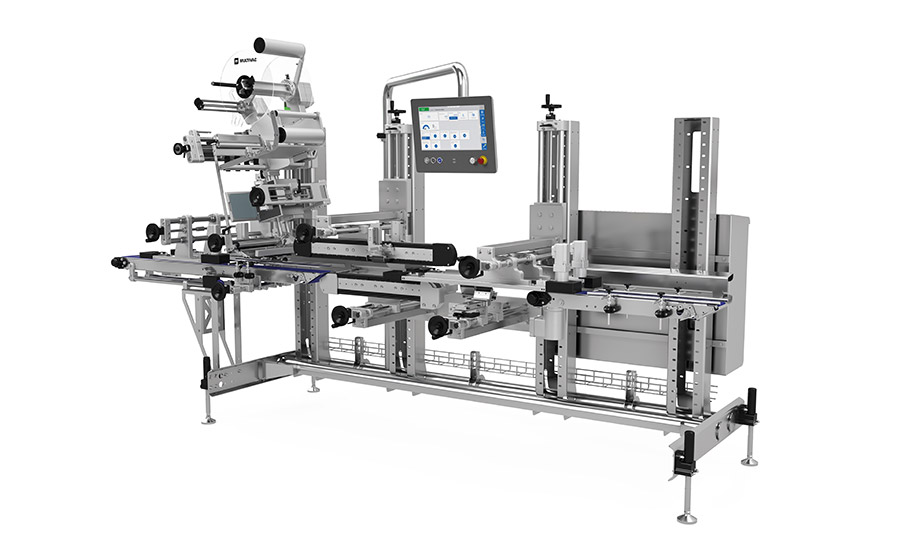

Upgrades to labelers are enabling processors to produce more attractive packages. Photo courtesy of Multivac US

Placements in a freezer or refrigerator, for instance, will influence label and shrink sleeve selections, she notes. “Manufacturers must carefully assess these variables to choose the right stock, film, inks, adhesive, and lamination for optimal performance and durability,” Gurland states.

One size does not fit all

Container type will impact material choices as well, she notes. Shrink sleeves, for instance, are full-color, 360-degree printed labels that utilize heat in the application process to conform the label to the shape of the container, is a better option for unique or hard-to-label shapes, Gurland says.

While package size and shape also are key factors in determining the most appropriate labeler, perhaps most vital is maintaining operating efficiencies by ensuring the equipment can support the proper line speed. This involves the rate the production line is designed to run based on the capacities of the related equipment, says Justin Slarks, director of marketing for Sleeve Seal, a Little Rock, Ark.-based shrink label equipment provider.

“It creates a bottleneck if any piece of equipment runs slower than intended for any amount of time as the downstream machines will match that speed,” he notes. “There then will be a surge of product running down the line at a temporarily higher speed once the bottleneck breaks loose.”

Among the recent technology upgrades are improvements to the software, or “brains” of a system, Mack notes. “These enhancements are making printing and labeling equipment easier to set up and use, easier to service, and more capable of integrating with upstream and downstream pieces on the packaging line,” he states.

The launch of enhanced vision inspection systems that integrate with labeling systems to verify each package has the proper label and printing is enabling processors to generate further operational efficiencies, Mack says. “It is a big improvement over having a person doing periodic checks of a handful of packs,” he states.

Labeling systems also are operating more quickly and accurately to keep pace with changing processor demands, notes Darrell O’Brien, vice president of sales at KDV Label, a Waukesha, Wis.-based custom label manufacturer.

The best design solutions will vary by product. Photo courtesy of Multivac US.

This includes the ability to stabilize the container or bottle during the application process for a consistent appearance, he states. Additionally, more labeling devices feature excellent tension control, expandable cores, and peel plates that can support the softer, more flexible film label base materials and film liners that are increasing in popularity, O’Brien adds.

Advanced designs are increasing efficiencies in shrink sleeve labeling as well, Slarks says. He notes that systems are minimizing operator input or guesswork and only allow the labeler to run if the axial adjustments are correctly set.

Become a standout

In addition, technologies are enabling operators to produce labels and shrink sleeves that both enhance a brand’s appearance and provide more information to consumers, Gurland notes. Extended content labels, for instance, have space for such additional elements as games, promotions, recipe booklets, and coupons, she states.

The use of pressure-sensitive, tamper-evident labels, meanwhile, are enhancing food safety by indicating if a product has undergone manipulation. Multi-pack sleeves also are providing dual compartments for sales promotions and to maximize branding space and secure products, Premium Label & Packaging Solutions’ Gurland notes.

Also available are specialty sleeves that block light and extend the shelf life of dairy products, as well as more recyclable materials, she says. “Emerging recyclable label and shrink sleeve constructions can enhance the brand’s desire to promote its concern for resources,” Gurland states.

Equipment, meanwhile, is becoming easier to program with memory storage for basic label formats so operators can perform changeovers quickly and precisely, O’Brien says.

He notes that the most effective labeling systems will suit a specific package or product. Gallon and half-gallon containers, for instance, typically require wipe-on applications and heat shrink is best for higher-end value-added products.

“The specialty products that command higher prices at retail, such as vitamin-fortified beverages and specialty flavored milks, favor shrink sleeve packaging methods that provide 360-degree graphics that run at significantly slower application speeds,” KDV Label’s O’Brien says.

Higher-volume, lower-price value-added products trend toward the more economical narrow-gauge film wraps that are available in roll-to-roll form that operators cut, glue, and apply at the filling location, he says. “They require a less expensive label that runs at faster application speeds,” he states.

Operators seeking the most appropriate solutions should determine line running speeds and container sizes before selecting labeling technologies, O’Brien suggests. Other considerations include label size and material; where label application will occur in the manufacturing process, such as pre-fill or post-fill; if there will be expansion and contraction after application; and whether moisture or condensation will be present, he says.

Teaming with a trustworthy equipment manufacturer with ample experience and a proven history can be vital when analyzing and choosing the best alternatives, Slarks says. “Finicky labeling equipment that isn’t up to the task is going to lead to headaches,” he states.

The vendors also must understand the unique processing requirements of each facility, according to Multivac’s Mack. Yet, while technology manufacturers can ease the implementation process, dairy processors still must conduct their own upfront examinations, he says.

Creative colors, including those for pressure-sensitive labels, can call attention to products. Photo courtesy of Premium Label & Packaging Solutions.

This can include calculating the potential cost savings from incorporating innovative systems and selecting the appropriate in-house staffers to participate in the selection process, Mack notes. He adds that it is important that employee input does not go “unheard and unconsidered. Being open to hear and consider new ideas is not always easy.”

Label and shrink sleeve developers that understand each stage of the manufacturing process also can provide valuable assistance to dairy processors that are seeking to change a format, such as going from a pressure sensitive label to a shrink sleeve, Gurland states. Such suppliers should be knowledgeable about all types of packaging equipment and recognize the importance of meeting the production needs of co-packers as well, she notes.

What lies ahead?

Moreover, operators should review both current and future demands when making purchasing decisions, O’Brien says, which could involve projecting future operating speed and component requirements.

“Talk to a dairy label specialist and see which materials, adhesives, and liners are necessary to hit those needs,” he notes. “Industry insiders in equipment, labels, and packaging films can provide a shortcut to a solution that is already in use in the industry and adaptable to your needs.”

Processors also should search for innovative technologies before their current equipment malfunctions to reduce the threat of downtime, Mack states. “Come into a project with concrete measures of success and share those with the supplier partner in the initial discussions,” he says.

Along with incorporating the most functional equipment, processors must ensure that staffers receive the necessary training to operate the technologies, Mack notes. “Even the most advanced printing and labeling systems are rendered useless without the right knowledge on how to use and maintain them,” he states.

Operators can face further obstacles when moving to situate newer and more effective technologies in facilities. Limited floor space, for instance, can prevent processors from leveraging key designs, O’Brien says.

Going against tradition and incorporating unique printing so that products stand out in stores can be burdensome as well. Gurland notes that there is great similarity among most package and label colors and the universal color coding of milk also makes it hard to create distinctive looks. “It’s difficult to differentiate products on retail shelves or online when most items have the same container shape, similar text, and an almost identical color palette,” she states.

In response, processors should get creative and consider using bold designs instead of the frequent baby blue and pale yellow to attract attention, Gurland says. “Shrink sleeves and labels offer opportunities for eye-catching specialty effects and finishes that can set the product apart,” she states. “Tactile coatings can also provide a pleasing experience for consumers, and some are willing to pay extra for it.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!