Ways to best protect the safety of dairy products

Dairy processors must manage a host of variables to protect products.

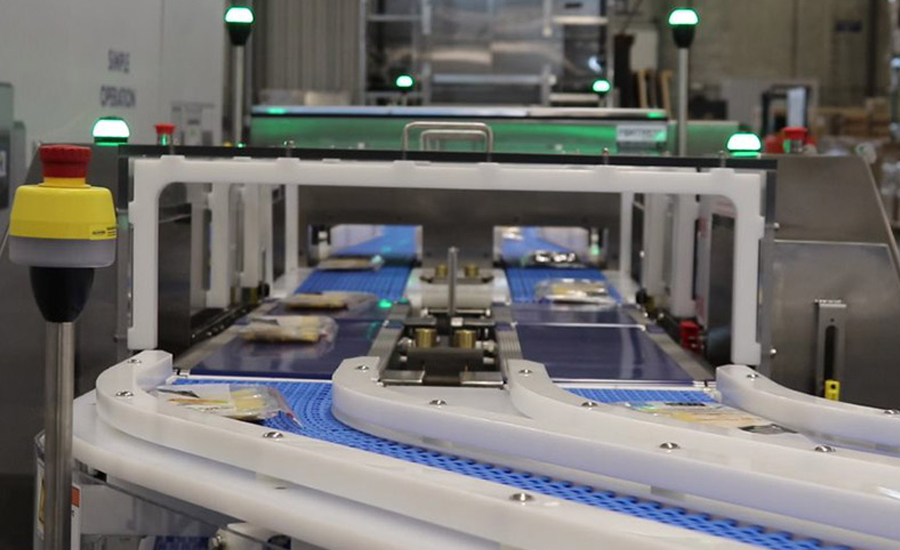

Effective sanitizing of dairy processing plant equipment requires the proper disassembly of devices. Photo credit: Multi-Conveyor LLC.

Protecting dairy products during production and transportation is a vital, and often arduous, endeavor. Successfully safeguarding ingredients, equipment, and facilities requires that processors adhere to a wide range of measures that incorporate technologies, cleaning methods, and employee education.

Operators must work to keep processing equipment and facilities free of pathogens and guard against the threat of metal contaminants in products while tracking the origin and movement of dairy ingredients and products along the supply chain.

“Dairy products are remarkably complex and involve a host of different chemistries,” says Mathew Bartkowiak, vice president of corporate responsibility and development at Nelson-Jameson Inc., a Marshfield, Wis.-based food safety sanitation material supplier. “Each product demands specific attention to numerous variables. An understanding of foreseeable hazards helps to determine the right implementation of key preventative controls.”

It’s also essential that processors focus on averting incidents rather than “chase down problems after they happen and forensically figure out what went wrong,” he states. Such a focus will help identify the necessary tools for temperature and environmental monitoring and sampling and the proper use of personal protective equipment.

Operators also can divide rooms in a facility into separate color-coded areas to prevent cross-contamination while implementing the most appropriate sanitation and maintenance programs, Bartkowiak says.

“Food safety is not a static checklist; it’s the establishment and maintenance of a targeted and robust culture within every plant,” he notes. “From onboarding and consistent reaffirmation to training and education on food safety standards and practices, the best food safety programs think holistically about how not to only do the right things, but to do those things with a sense of purpose, pride, and service to their customers.”

Foodborne illness threats during production are among the most serious concerns as pathogens, such as listeria monocytogenes, salmonella, and E. coli, can create potentially life-threatening situations, says Vanessa Coffman, director of the Alliance to Stop Foodborne Illness, a Chicago-based public health organization focusing on the prevention of illness and death from foodborne pathogens.

Pathogen prevention is paramount

“While listeria monocytogenes and salmonella are broadly relevant across different dairy products, their specific risks can vary, depending on such factors as moisture content, acidity levels, processing steps that include pasteurization and fermentation, and ingredient quality,” she states. “Dairy processors must tailor their food safety measures accordingly, including following rigorous sanitation practices, monitoring raw materials, and adhering to regulatory standards.”

Matt Westerfield, senior manager at Atkore Calbrite, a Harvey, Ill.-based processing equipment supplier, concurs: “Bacterial growth and contamination are always a concern in food and beverage manufacturing. Cleanliness and hygiene are critical.”

He explains that operators can help minimize incidents by leveraging stainless-steel conduit equipment that is easy to clean and able to prevent corrosion from washdowns, cleaning agents, and other chemicals.

It also is crucial that processors have a strong food safety culture that emphasizes protection, Coffman states. This includes robust employee training; a workplace that values addressing issues when they arise; and managers that encourage and reward workers “for taking the right steps every day,” she notes.

“Without a positive and mature culture, testing, cleaning, and monitoring will have little impact on overall product safety,” Coffman says. “People need to care about what their findings mean and take swift corrective actions when something is amiss.”

Workers in such an environment will also learn how to properly disassemble equipment for cleaning and combat bacterial menaces throughout the processing facility, says John Butts, founder and principal of Food Safety by Design LLC, a St. John, Ind.-based consulting firm. A key objective is to clean the nooks, crannies, and surfaces that can harbor pathogens, he notes.

“Organisms that can be found on floors in a pathway of movement have a good chance of contaminating a contact surface or the product,” Butts states.

Processors can more effectively sanitize production environments by reducing the use of high-pressure rinsing that can “embed microorganisms into protective locations deep into the equipment and facility,” he says. “It is a rare situation in which operators need to use high pressure.”

The use of metal detectors can reduce product contamination and injury to consumers. Photo credit: Fortress Technology Inc.

Be willing to correct course

While most dairy processors will achieve superior results with low-pressure rinsing, many operators are reluctant to change their high-pressure habits, Butts states. “Persons performing sanitation are going to do what is easiest, as that is human nature,” he says, noting that workers seeking to more quickly clean facilities are apt to use bullet nozzles, which direct greater rinsing force, instead of more effective fan nozzles.

In addition to bacterial hazards, processors must guard against metal adulterants in dairy products, says Robert Slauson, assistant sales manager for Advanced Detection Systems, a Milwaukee-based metal detection equipment manufacturer. Parts that can emanate from equipment and workers include bearings, screens, blades, nuts, knives, bolts, vessels, pipes, wire, tools, staples, pens, paperclips, sensors, batteries, temperature probes, and injection needles, he notes.

“A bite into a metal contaminated product can result in broken teeth, being impaled, or lacerations in the mouth,” Slauson states. “This is usually followed by a lawsuit and possible product recalls.”

Operators can reduce contamination by situating metal detectors at the end of processing lines and leveraging optimal detection equipment, which will vary in accordance with the type of product under production, he says.

Conveyor mount detectors, for instance, are effective for analyzing solid or packaged foods while pipeline units examine liquid products, Slauson states. After a pipeline detects metal, a downstream reject valve will actuate and divert the product flow to ensure removal of the contaminant, he notes.

It is crucial that metal detectors undergo proper setup and daily testing to maintain accuracy, Slauson says. Nevertheless, because detectors gage the conductivity of elements, the system is susceptible to “product effect,” which can include false positive readings from such dairy ingredients as water, salt, fats, and acids, he states.

While lowering the detector’s sensitivity can reduce product effect, the measure may also lower metal detection accuracy, Slauson notes. “Product effect cannot be eliminated entirely, but there are ways to reduce or minimize its impact,” he says. This includes decreasing the amounts of products simultaneously undergoing inspection and ensuring that products pass through detectors in uniform manners, such as being horizontal, vertical, or diagonal, he adds.

Processors also face food safety hazards during the transportation of products from plants to retail outlets. Risks stem from potential disruptions in the cold chain, which can occur during warehousing, distribution, delivery, and storage along transit routes, says Shipra Pareek, senior account manager, food retail at NSF, an Ann Arbor, Mich.-based provider of testing, inspection, certification, and advisory services and digital solutions.

“Such disruptions can result from temperature fluctuations, inadequate sanitation during handling, equipment malfunctions, and cross-contamination from other products or surfaces during transit, she notes. Milk, for instance, requires strict temperature control to prevent bacterial growth, while cheese, though less susceptible due to fermentation, can still face contamination risks if not stored properly,” Pareek states.

Processors should follow a multi-faceted strategy to safeguard products, she says. “This includes ensuring that stringent quality control and measures are implemented at each stage of production and transport,” Pareek notes.

Traceability systems enable operators to track the movement of dairy products and ingredients during transit. Photo credit: Penske Logistics.

Stay cool

Maintaining a consistent cold chain requires vigilant temperature surveillance to inhibit microbial growth and preserve product freshness, Pareek notes.

“Dairy products are at an especially higher risk of spoilage due to temperature abuse during transportation,” she states. “Temperatures must be appropriately managed in refrigerated vehicles and products must be transferred and delivered at each point in the supply chain quickly and efficiently.”

Operators can further minimize contamination risk by enforcing rigorous sanitation protocols for equipment, vehicles, and personnel, which includes comprehensive training programs to ensure staff are well-versed in food safety procedures, Pareek says.

Having solid traceability protocols that enable dairy processors to track products and ingredients through all steps in the supply chain is vital as well, analysts note.

“Processors can use traceability data to identify food safety issues both internally and across supply chains,” says Sara Bratager, senior food safety and traceability scientist for the Chicago-based Institute of Food Technologists. “A robust system can minimize the impact of foodborne illnesses.”

She notes, for instance, that dairy processors might combine product defect data with traceability information to determine if products with undesirable microbial counts originate from a certain production area or supplier. “Traceability can be an invaluable tool for root cause analysis and continuous improvement, which enhances overall food safety,” Bratager states.

Traceability is also crucial for ensuring that retailers and consumers have confidence in a processor’s food safety measures, says Angela Bello, QA document specialist and sensory coordinator for Global Organics Ltd., a Cambridge, Mass.-based ingredient supplier.

“Companies can closely monitor higher risk items and ensure the safety of their products,” she states. “These monitoring programs help identify and address issues promptly, reducing the likelihood of sicknesses and recalls.”

While traceability systems can be challenging to implement, the effort is “worth it,” says Steve Statler, chief marketing officer of Wiliot, a San Diego-based traceability technology developer. He notes that operators must have support from company leadership and technology, supply chain, and operations personnel for an effective program. Such backing requires a significant amount of cross-functional cooperation and spending, Statler states.

“Speed and precision of tracking within product supply chains can save lives and money,” Statler concludes. “We cannot risk the lives of customers unnecessarily and waste food that could have been saved with a fast trace.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!