Heat exchangers vital in modern dairying to kill bacteria in raw milk and extend shelf life

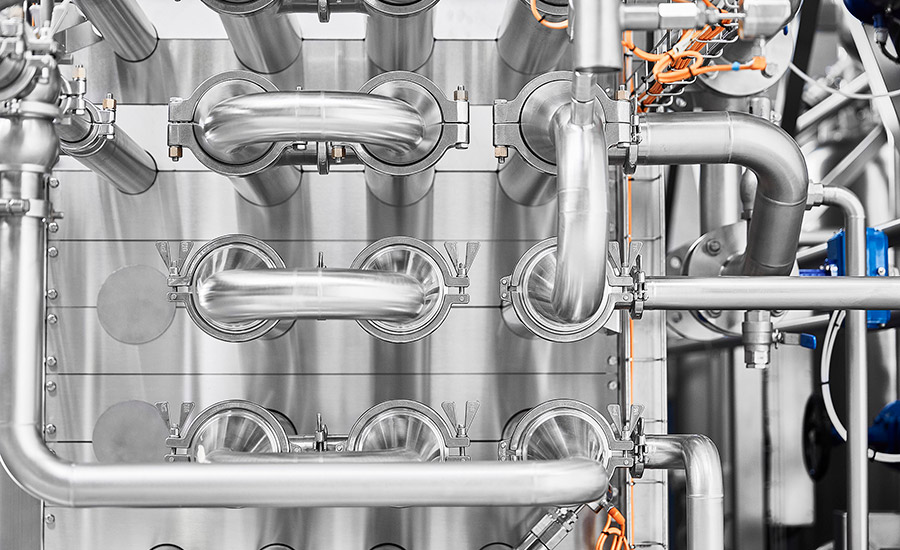

Where gentle handling or thorough mixing is required, then scraped surface heat exchangers, such as the HRS Unicus Series, is recommended. Photo courtesy of HRS Heat Exchangers.

“The Heat is On” is an upbeat song recorded by Glenn Frey for the 1984 movie, “Beverly Hills Cop,” which starred a 23-year-old Eddie Murphy as a street-smart Detroit detective who visits Beverly Hills, Calif., to solve the murder of his best friend. In the world of dairy operations, heat exchangers are “bringing the heat” and “solving” pasteurization and sterilization challenges in raw milk, making it safe to drink and extending the shelf life of milk, yogurt, creamers, and more.

While the name contradicts itself, heat exchangers also are required to “cool down” ice cream mixes quickly to 4 degree Celsius or lower so that the product retains its viscosity and melts smoothly.

When Dairy Foods asked Matt Hale, global key account director at HRS Heat Exchangers in Marietta, Ga., whether heat exchangers are used most for heating up or cooling down, he replies “both.”

He explains that the requirements of modern dairying is to be able to control the temperature of products as most dairy products have to be heated, for example, at a high-temperature, short-time (HTST) method at not less than 190 degrees Fahrenheit for 15 seconds, for pasteurization and then immediately cooled down for processing, packaging or storage.

“For example, most complete pasteurization systems will include both heating and cooling sections,” Hale explains. “Because of this, the use of heating and cooling systems is roughly equal across the industry, although cooling may be more common in the primary production phase (i.e., lowering the temperature of fresh milk immediately after milking on farm).”

But how exactly do heat exchangers work?

“Heat exchangers work in the same way as a radiator, transferring heat (or cold) from a source (the service side) to a product,” Hale relays. “For example, hot water or steam may be generated by a boiler to provide a heat source or refrigerated water or glycol may be used for cooling. Depending on the heat exchanger design, the service fluid flows around the pipes carrying the product.

“The heat range is usually determined by the quality parameters of the product and the service fluid, so is typically just above freezing (e.g., 2 degrees Celsius) to around boiling (100 degrees Celsius),” Hale continues. “Adjusting pressure can also be used to manipulate factors such as boiling points, etc.”

Although there are plenty of heat exchanger options to choose from including a number of specialty designs, Hale suggests the three most common types of heat exchangers, which vary depending on application, are:

- Plate heat exchangers: uses larger metal plates to transfer heat between simple viscous fluids such as water, milk and some thin oils.

- Tubular heat exchangers: have several different types, including annular space, double tube and multitube, but the biggest influence on the efficiency of tubular heat exchangers is the type of tube used.

- Scraped surface heat exchangers: useful when intermittent or continuous scraping of the heat transfer surfaces is carried out to keep heat transfer surfaces free of fouling and to maintain clean conditions. These are well suited for products like chocolate or butter that are viscous, sticky or need some degree of crystallization.

Hale maintains that corrugated tubes are far more efficient at transferring heat than smooth ones. Not only are they associated with lower maintenance costs, they provide high working pressure and high working temperatures to process particulates or fiber products.

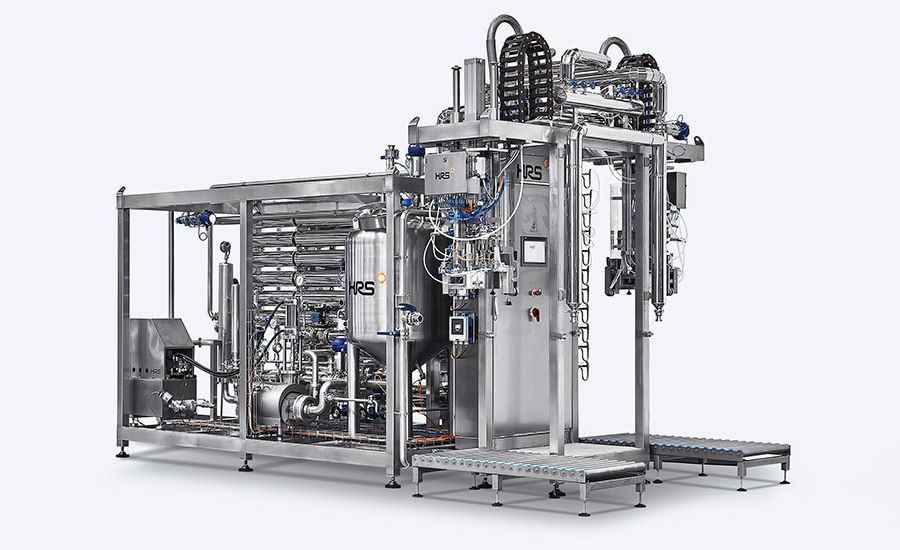

According to Hale, HRS Heat Exchangers, for more than 40 years, have gained a reputation for producing highly efficient tubular heat exchangers which provide unrivalled heat exchange capacity combined with consistent performance in a relatively small operational footprint.

“The key to this is our use of corrugated tube technology, which has many benefits over the use of smooth tubes in tubular heat exchangers, in particular, heat transfer and energy efficiency are increased, and fouling is minimized meaning that units can be more compact and economical, and cleaning and servicing requirements are reduced,” he states.

These benefits equate to longer, stronger performance.

Shane Krieger, service project manager at Nelson-Jameson, on the other hand, notes that a plate heat exchanger facilitates the transfer of heat between a hot or cold product by use of a series of plates.

“Products are sealed off from one another with gaskets to prevent cross contamination,” Krieger explains. “A typical plate heat exchanger in the dairy industry is used to heat products up to 165 degrees Fahrenheit for pasteurization and may be used to cool product to 33 degrees Fahrenheit for storing or transferring.”

Plate heat exchangers are a very cost-effective way to heat/cool products, particularly since there are regeneration sections designed to “recover surplus heating/cooling from products that are already to ‘temp’ and pre-heat or cool product elsewhere in the process,” Krieger adds.

Founded in 1947, the Marshfield, Wis.-based company offers a variety of heat exchangers including Plate, Tube and Shell and Scraped surface heat exchangers.

As well as individual heat exchangers, HRS offer a range of complete processing systems for the dairy sector, including its Asepticblock series of contained pasteurizers and sterilizers, concentration and evaporation systems, cleaning systems and aseptic fillers. These can be integrated with existing lines or skid mounted for ease of transport and installation, Hale says.

Heat exchange equipment dependent on application

Experts note that the type of functional heat exchanger needed within a dairy processing plant is very much dependent on the nature of the product being produced.

HRS Heat Exchangers’ Hale explains: “For example, for plain milk, plate heat exchangers (PHEs) or smooth tube ‘shell and tube’ designs may provide sufficient heat exchange capacity. However, for thicker materials including creams, custards and cheese, corrugated tube or scraped surface heat exchangers may be more suitable.

“For the most challenging applications, where gentle handling of particles is required (for example yogurt containing fruit pieces, smoothies, etc.), or where thorough mixing is required (as used in some traditional curd production techniques), then scraped surface heat exchangers will be required,” he continues. “Depending on the level of heat transfer and product mixing required, and whether the product needs gentle or robust handling, then rotating and reciprocating designs are available.”

When it comes to equipment cost, Nelson-Jameson’s Krieger points out that like much of the equipment used in dairy processing, the cost of heat exchangers vary depending on type, products, throughput demand, material makeup, and amount of automation within a dairy plant.

The heartbeat of the dairy plant

Both Hale and Krieger rank heat exchangers “extremely high” in importance within a plant since dairy processors need this mighty system when pasteurizing and sterilizing milk, a prime ingredient in the vast majority of dairy products.

“Hands down they are the “heartbeat of the plant,” Krieger stresses. “If you can’t pasteurize your product, it’s not good for human consumption (In most cases). If you are unable to cool your product, you risk spoilage as well as decrease the transportation options,” he states.

Hale concurs: “In our experience, heat exchangers are the most important, and certainly the most energy-efficient, technology used for pasteurizing and sterilizing milk, as other technologies, such as ohmic heating, are not currently suitable for most dairy products.”

Like virtually everything in the dairy industry, today’s latest iterations of heat exchangers are engineered to be more effective and efficient in transferring heat across plates or tubes, as the words “heat exchangers” suggest. But the plates also have evolved to utilize heat to assist in the exchange process, whether it be in the heat exchangers itself or another area of the dairy plant, Krieger states.

“Auto open/close units are manufactured within the past 10 years that allow for a speedier open/close of the unit for decreased downtime as well as being safer for employees to open/close,” he adds, noting that dairy processors should consider “product type, efficiency, the availability of spare parts and serviceability” when selecting the most productive heat exchangers to keep dairy operations humming along.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!