ESL and aseptic have a long shelf life

Specialty packaging market expected to grow significantly for the remainder of the decade.

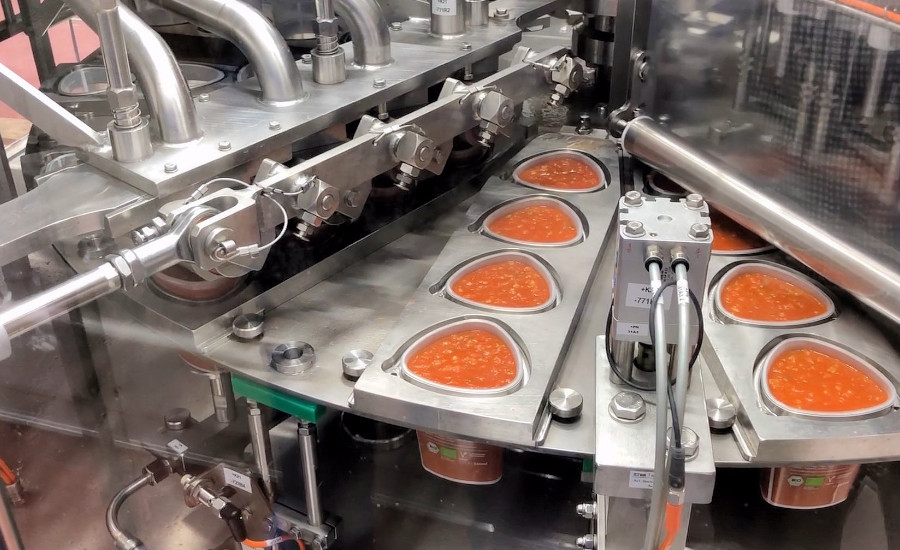

Video courtesy of GCShutter via www.gettyimages.com

The packaging market is a true slam dunk in terms of growth, led by aseptic and extended shelf life (ESL).

Aseptic packaging uses a process in which operators prevent microorganisms from entering a package during and after packaging. During aseptic processing, operators fill a sterilized package with a commercially sterile food product and seal it within the confines of a hygienic environment. Sterilization of the food or beverage occurs with quick exposure to ultra-high heat, before rapidly cooling at an ambient temperature.

The aseptic packaging market size was valued at $66.48 billion in 2021 and is projected to reach $152.65 billion by 2030, growing at a compound annual growth rate (CAGR) of 10% from 2022 to 2030, according to Verified Market Research.

“Because of the increased demand for ready-to-eat food products, the aseptic packaging market is expanding rapidly. Increased urbanization and packaging industry growth has resulted in an increase in demand for aseptic packaging, particularly in the Asia Pacific and South America’s emerging economies,” the report states.

ESL’s growth is big also

The related ESL category also has a long shelf life — literally. ESL has a refrigerated shelf-life of 21 to 45 days with some manufacturers claiming a shelf-life of up to 90 days. It is produced by two principal technologies: Thermal processing using more severe conditions than pasteurization but less severe than ultra-high-temperature (UHT) processing; and non-thermal processes such as microfiltration and bactofugation, usually combined with a final thermal pasteurization treatment to meet regulatory requirements.

The Dairy Farmers of America (DFA) recently made a big bet on ESL, when it announced in August the acquisition of two ESL processing facilities from SmithFoods.

The processing plants, located in Richmond, Ind., and Pacific, Mo., produce a variety of extended shelf-life dairy and nondairy beverages, ice cream, and shake mixes for both retail and foodservice customers. The facilities will become part of the DFA Dairy Brands division and will operate as Richmond Beverage Solutions and Pacific Dairy Solutions.

“There is increasing consumer interest in extended shelf-life dairy products, and this acquisition aligns with our strategy to increase commercial investments and expand our ownership in this space,” says Pat Panko, executive vice president of DFA and president of DFA Dairy Brands North. “With the addition of these plants, we have an opportunity to not only grow our customer base, but also create synergies between our other ESL and aseptic facilities.”

Experts weigh in

To learn more about the aseptic and ESL market, Dairy Foods reached out to several industry executives to provide plenty of advice regarding what dairy processors should consider before purchasing aseptic/ESL equipment, when they should upgrade equipment, plus much more. Providing responses are Todd Delebreau, director of sales, HART Design & Manufacturing Inc., Green Bay, Wis.; Jeff Arthur, technical sales director, Covington, La.-based Allpax, a ProMach Product Brand, (who answers from a perspective of ESL and aseptic using retorting technology or in-container thermal sterilization); Pierpaolo Mattana, sales director of beverage & filling, GEA North America; Gina Abruzzini, vice president of engineering, Woodland, Wash.-based Statco-DSI, a ProMach Product brand; Max Davis, general manager at Waldner North America, Wichita, Kan.; Patrick Carroll, president, IMA Dairy & Food USA, Leominster, Mass.; David Miles, executive vice president, Raleigh, N.C.-based MicroThermics Inc., who stresses his answers come at these issues from a point of research and development of new products that will be produced at commercial facilities; Chad Ellis, senior project manager, Manassas, Va.-based Shibuya Hoppmann Corp.; and David Watson, category director of food closures for Burlington, Ontario, Canada-based BERICAP.

In looking at how ESL and aseptic have advanced during recent years, Ellis says: “The most significant advancements in both ESL and aseptic technologies have been the savings on utilities and total cost of ownership (TCO) as well as overall system footprint reduction. Specifically relating to aseptic, certain technologies (e.g., electron beam, preform sterilization) have greatly reduced the utilities usage compared to the conventional approach. Electron beam (EB) in particular has proven to be the leader in TCO savings with our customers that have both H2O2 and EB technologies in their facilities.”

The advancement has steadily progressed over the past few years with more and more customers demanding ESL options, Delebreau adds. “ESL and sustainable packaging are the two most inquired about features and options requested by customers,” he says. “Shelf life can be increased by as much as 50% dependent on the product.”

Aseptic and ESL have advanced through several channels from a technology perspective, Carroll notes. “When considering bottles, the package sterilization chambers have become smaller, the preform is often sterilized before the bottle is made, thus the blow molder is attached to the filler. The overall complexity of the systems have been reduced since both machine suppliers and producers have a better understanding of the process and system requirements to meet the consumer demands.”

ESL and aseptic products have progressed in both product diversity and widespread availability, Abruzzini states. Products have evolved to showcase the nutritional benefits inherent to dairy, with enhanced protein and reduced sugar, unique flavors, and eye-catching packaging. While ESL increases the geographic reach to make these products readily available domestically, aseptic has pushed the boundaries further abroad, she says.

In recent years there has been strong focus on sustainability, both in operations and packaging types, Mattana adds. “This includes reducing equipment footprint, energy consumption, water usage, and bottle weight. In packaging, customer demands have forced innovation and new designed systems that can aseptically fill into aluminum bottles and glass, rather than the most commonly used PET and carton style containers.”

A beverage that has been properly filled in aseptic conditions can have a guaranteed shelf life of 12 months or more, while products filled in ESL conditions and properly stored can reach and exceed a three-month shelf life, Mattana relays.

“The packaging types used in aseptic processes are thoroughly tested in each individual system before production to ensure only safe products are delivered to the final consumer,” he adds. “For high-acid products like fruit juices and isogonics, we also noticed a significant transition from hot fill to aseptic filling. Reducing the container cost is the most important driver for the change.”

Regarding retorting, extending the shelf life of containerized dairy-based foods and beverages via this route is a well-established and trusted method for food preservation, Arthur stresses. “Retorting provides the ultimate shelf-life, without refrigeration, versus other types of processes — up to two years or more. Retort technology continues to evolve and become more efficient.”

Industry challenges

Although the growth of aseptic and ESL appears to be off to the races, inherent challenges still exist in these game-changing technologies.

Challenges in consumer perception and current regulations have slowed some of the innovation and short-term growth potential for the industry, Abruzzini asserts.

“Better messaging and descriptive advertising will help educate consumers about what ESL entails, and that there’s no added preservatives. Likewise, misnomers about aseptic (sounds like ‘septic’) can also be overcome through proper descriptive packaging, emphasizing the wholesome goodness and natural quality of the product inside,” says the Statco-DSI executive.

Davis also pointed out ESL and aseptic messaging is challenging. Hence, the public relations effort is perhaps its greatest challenge.

“Client understanding around what the best buy date is remains limited. The further out this date is pushed, the more of a struggle,” he states. “A big challenge for customers is figuring out whether their product should be aseptic or ESL. The threshold seems like it is binary for customers. They either have to be aseptic or they have to ‘settle’ for ESL. I think this is not the case.”

On a related note, changing consumer habits are another challenge, Miles notes.

“The plant-based beverage market segment is growing dramatically. However, these products often require different processing conditions than traditional dairy products. They often require higher homogenization pressures, or more extreme thermal processes to provide the required reduction of bacteria, while still providing a process that is gentle enough to maintain high product quality.”

Additionally, as these market segments continue to grow, processing capacity will also need to grow, Miles adds.

Beyond consumer relations, the cost of the technology and skill level of employees remain an ongoing challenge for producers, Carroll stresses. “Some of the smaller producers cannot afford the technology or skill level of employees to use the technology,” he says. “The machine suppliers continue to provide more economical and user-friendly systems based on market demand, the use of alternative sterilization technology, such as UV and pulsed light technology, has helped dairy producers reach more advanced systems with only a moderate increase in machine pricing.”

Ellis also points to the labor obstacle. “One challenge is finding the more advanced technical labor force required to accommodate both regulatory and operational duties that come with ESL/aseptic campaigns,” he says. “To help overcome this transition, owners should source suppliers that have extensive experience in the ESL/aseptic industry with a proven history of successful installations such as Shibuya which has installations both in the U.S. and worldwide.”

Local support, proper training, and responsiveness to owner’s needs is also critical when establishing a partnership with an ESL/aseptic supplier, Ellis continues.

Improving cost/scale efficiency, further simplify the manufacturing process, and enhancing barrier and shelf life while using TCO friendly materials with materials reduction is another challenge, maintains Watson.

“Quite simply the best way to overcome these challenges is to continue to apply a process of harmonization and standardization, which should further refine the industrial capability of aseptic and ESL containers,” he says.

Mattana points to the large investment involved as an additional challenge to overcome.

“The strict testing trials are lengthy and an additional drain on manufacturing resources. As market trends change at a seemingly increasing rate, manufacturers struggle to pivot and adapt to the demands. This can force brands to compromise on their products or even prevent them from launching entirely,” the GEA North America executive says.

What to know before purchasing equipment

Considering the financial investment involved, should dairy plants purchase aseptic and ESL equipment? What must they know before making this decision?

“Generally, I think processors that are considering their first aseptic/ESL program need to review the size/scale of the products they sell, regional turnover of filled product, established supply chain vs outlay to determine if an aseptic/ESL program is right for their business,” BERICAP’s Watson says. “An aseptic/ESL line can allow a dairy to expand their reach and shelf-life in market. However, there remains a limited amount of ‘stomach’ which doesn’t always assure expansion and/or additional consumption.

Furthermore, depending on a dairy’s current establishment in the cold supply chain (where American’s typically buy their milk) an aseptic/ESL program might not be any more effective especially if turnover is short and/or geographic reach is limited, Watson adds.

For Davis, the single most important component is where the processing and the packaging meet. “Ensuring that these two processes are designed and executed in lock step is the single factor most likely to lead to a successful project,” the Waldner executive advises.

Miles recommends first asking, “What types of dairy products are they going to process? Conventional milks and flavored milks or will they be producing protein-fortified beverages? This will determine the processing technology they will use such as indirect or direct. What types of containers will the consumers of the products, or the manufacturers want? The container style not only affects the products quality, but also its image.”

The Dairy producer should consider what products and package sizes they feel they need. Adding these in later in many cases is not possible, or very expensive and disruptive, IMA Dairy & Food USA’s Carroll adds.

“Their distribution channel should be carefully examined, perhaps they don’t need aseptic and the refrigerated chain is more than sufficient. In many cases, when considering sensitive products and longer shelf-life requirements aseptic is the only choice.”

The main thing is to determine what their end users are looking for now as well as in the future. Just because ESL is not in their periphery not does not mean that their customers will not be requesting in the future, HART Design & Manufacturing Inc.’s Delebreau maintains.

Allpax’s Arthur shares a similar sentiment, stating processors must not only consider today’s needs, but also tomorrow’s because some types of processing equipment can be very specific and limited in their breadth of capabilities.

“Batch retort systems are the most flexible in regard to handling various products and packages, when compared to other types of in-container thermal sterilization systems, and even aseptic and ESL (refrigerated product) process systems,” he says. “The volume of product, extent of the capital investment, and when the product will need to be introduced to the market can also be factors in selecting the right processing system, and/or if it would be best to consider using a co-packer.”

In the end, the three most important deliverables are quality, throughput, and efficiency, experts note.

Once initial volumes, planned expansion volumes/SKUs, and plant location have been decided upon, the initial design phases will consist of: a mass balance of the facility — from ingredient receiving through storage, separation, blending/processing, through filling, material handling and cold box (ESL) or dry warehouse (aseptic), Abruzzini suggests.

“The mass balance should be tied to expected production in order to determine optimum plant operations and efficiencies — and these should be leveraged to ensure performance fulfilment,” the Statco-DSI executive notes. “Processing and packaging design and subsequent equipment selections should be made based on such factors as: performance, flexibility/compatibility, longevity, maintainability/serviceability, sustainability and cost of ownership.”

Time to upgrade?

If a dairy plant already has aseptic/ESL machinery in place, the next big decision is when to upgrade the equipment. Mattana noted a well-maintained system can be operational for many years, but an upgrade may still be necessary.

“We find many customers performing upgrades based on their business needs. Usually, this is based on a change in production capacity or introduction or a new product,” Mattana noted.

Packaging equipment, especially when not consistently cared for, can age like non-ESL/aseptic milk, Davis maintains. “It’s essential to track OEE (overall equipment effectiveness) not only on the plant or production line level, but at the level of the individual piece of equipment. When this starts to decline, it’s time to conduct a root cause analysis.”

When viewing a current ESL/aseptic operation, it’s worth noting that the current equipment may be performing just fine for its original intended purpose, but it’s not uncommon that that original intended purpose has evolved, perhaps into different product SKUs, filler pairings, etc. In these instances, it’s best to take a more wholistic view of the operation, volumes, and SKUs from a mass balance perspective to determine limiting factors and bottlenecks, Abruzzini adds.

Shibuya has an aseptic system running now for 27 years, but this may be considered an anomaly. Longevity of the systems vary depending not only on the technology leveraged but the quality of components used by the manufacturer, Ellis reveals.

“For example, a system that utilizes PAA (peracetic acid) as the primary sterilizer may have shorter longevity than one that uses H2O2 due to the aggressive nature of the PAA on the various seals/bearings within the system. Those owners that opt for routine maintenance from the manufacturer typically observe longer life spans on the equipment as well.”

When the degradation of the critical components is visibly noticeable, it would be wise for the owner to consider upgrading their ESL/aseptic equipment,” continues Ellis.

Aside from when maintenance costs and downtime have a negative effect on finances, plants should look at long-term trends to see if their current equipment can accommodate processing requirements of the new products, adds MicroThermics Inc.’s Miles.

“The ability to process wider ranges of products, or new products, in markets where the processing capacity is low, but where demand is growing are opportunities for true growth.”

Potential downtime generally factors into whether upgrading current equipment in place is favorable vs. outright replacement with new equipment, adds Abruzzini.

“On a good note, advancement in technology with new equipment — particularly as it relates to seamless routing from and to multiple destinations — can help to leverage better process efficiency and substantially reduce product loss, thereby shortening the return on investment.”

However, it is important to note that due to supply chain concerns, dairy processors may need to plan out this upgrade many months before they need equipment. In fact, Delebreau recommends planning for this upgrade as soon as possible.

“With current global supply constraints, lead times on equipment and components has grown dramatically. Some equipment lines have a 12- to as much as 24-month lead time, so upgrading is typically not a quick process,” he says.

What the future holds

ESL and aseptic technology has already changed the dairy industry tremendously. What are some of the new technologies both available today and coming down the pike that can further alter the dairy industry?

Neither steam injection or indirect heating are new technologies, but changes and refinements in these technologies are being made to accommodate these new fortified products, Miles notes.

UV light treatments, high-intensity light treatment, HEPA-filtered air systems and antibacterial spray systems are areas that will always be continuously improving, much like sustainability technologies, adds Delebreau.

Filling valves have advanced to aseptically handle larger particles and pieces, which creates opportunities for new products to develop with chunks of fruit or other materials, Mattana adds.

“Thermal processors (Therma-Stat) that utilize direct product-to-product regeneration, dual balance tanks, and open architecture flash chambers to minimize product loss, utility monitoring and trending, replenishable homogenizer sterile air dampeners for extended runs, optimized controls with intuitive operator prompts, automated hibernation rates to conserve energy whenever the system is not in active production, source and destination phase detection monitoring to minimize product loss and to ensure there’s no adulteration, and the list goes on,” Abruzzini adds.

The technology around pulsed light has improved over the years. This has allowed producers to work with much more simplified technology when considering ESL systems,” Caroll reveals. “Many ESL/Aseptic systems today require the use of chemical sterilization, which results in higher operating costs, more complexity, and finally people required to operate these systems. Full aseptic systems today still require chemical sterilization.”

While the ability to remotely connect into processing equipment that is PC- or PLC-based has been available for years, many older systems do not have that capability and this technology is of paramount importance, Arthur reveals.

“The ability to remotely connect securely and troubleshoot processing equipment is game-changing in terms of reducing downtime, and this technology and related OEM services should be incorporated whenever possible,” the Allpax executive concludes. “The reduction in downtime and costs to service equipment can easily justify the investment both in existing and new equipment.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!