Avoid common filtration mistakes in dairy processing

There are many things you can do now to ensure that your dairy filtration system works effectively.

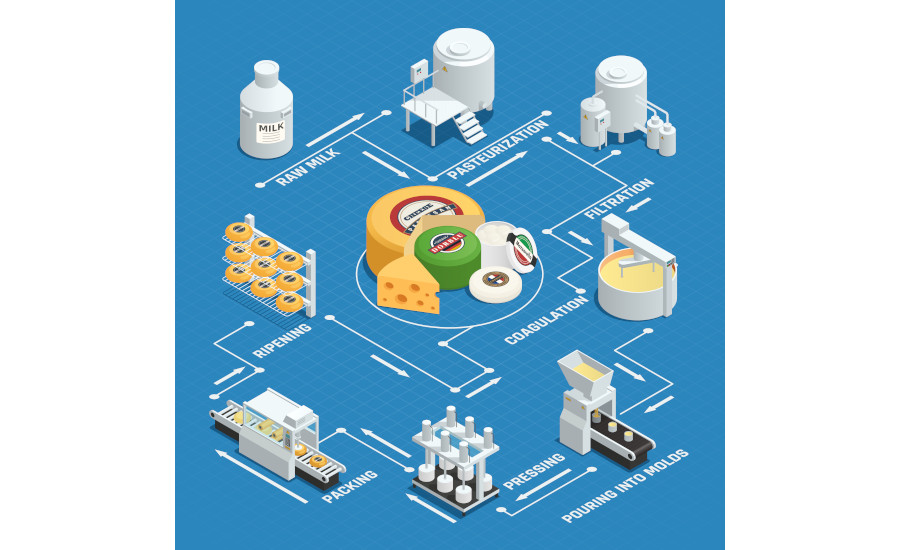

Liquid filtration plays a critical role in dairy processing, from reducing lactose to brining cheeses. Though today’s filtration systems are highly effective, they still require oversight to ensure they are working at peak performance. Consider the following mistakes to avoid when it comes to dairy processing filtration.

Mistake #1: membrane fouling

When deposited materials build up on the membrane surface, filtration efficiency is reduced, causing more energy to be used in the process. In dairy applications, some of the most common materials found building up along the membranes are lactose, whey solids and mineral salts. Membrane fouling can be found in both ultrafiltration and microfiltration and, if left untreated, could greatly impact the quality of product being produced by reducing pressure in the filter.

The potential solutions to membrane fouling are largely dependent on the type of buildup found. If mineral salts and sediment in the water supply are to blame, a pre-filtration system may help by removing those larger particles before they make it to the membrane downstream. Scheduled cleanings are also essential to ensure the filtration system is most effective, while a stronger chemical cleaning may be utilized less frequently, as needed.

Mistake #2: failure to test membranes

When contaminants — whether whey solids, sediment or even lactose in some applications — make their way through the line, the final product may be lost. Because membranes are one of the first lines of defense in your dairy processing plant, it’s important to test their efficacy regularly. Even low levels of sediment or mineral salt could be an indication that the membranes have been compromised, requiring cleaning or replacement.

Before you begin testing your membranes, it’s best to consult the manufacturer’s guidelines for your specific system. Many recommend conducting a bubble test, where the system is drained, then pressurized with compressed air. If large bubbles form while the pressure is rising, it’s likely the membrane is torn or compromised.

Pressure decay testing may also be used by pumping pressurized air into the module and monitoring it for a period of time. A high drop in pressure could be indicative of an issue with the membrane.

Mistake #3: old or improperly sized seals in the filter system

While membranes play an essential role in dairy processing filtration, sealants are just as important. These surfaces produce a seal between the clean stream of liquid and the stream filled with contaminants. If the seal is defective, either because the O-rings are worn out or the gaskets are improperly sized, the final product may be contaminated.

Prior to installation, be sure that the O-rings that will be used are chemically compatible with the liquid being filtered. Then, periodically inspect the seals to ensure they are installed correctly, fit tightly and are generally in working order. If an O-ring begins to lose its elasticity over time, replace it, and tighten or refit gaskets as needed.

Mistake #4: not prioritizing maintenance

For filtration systems to be most effective, they need regular maintenance. Without it, systems could see a significant drop in pressure over time due to buildup on the membrane. This not only reduces the efficacy of the system, it also requires more energy. The result could be longer system shutdowns and, therefore, a drop in productivity.

In addition to testing the membranes often, be sure to clean them and replace them as needed. The lifetime of the membrane is determined by its material, so it’s recommended to consult manufacturer’s guidelines here as well. Polymeric membranes, for instance, have a life cycle of one to three years. Regular maintenance, cleaning and replacement of old membranes will ensure your filtration system works at peak performance for years to come.

Best filtration practices for dairy processing

Don’t wait until you find contaminants in your line to think about your filtration system. There are many things you can do now to ensure that your dairy filtration system works effectively. First, monitor your system for membrane fouling. If pressure drops, this could be an indication that buildup has collected on the membrane.

Test, clean, and replace your membranes as needed to maintain pressure in the system and help keep your final product free of contaminants. In addition, inspect sealants often. A worn O-ring or loose gasket could allow unwanted minerals, whey solids or fats to make their way down the line, so fix or replace them when an issue is detected.

These should all be a part of your regular maintenance routine. Combined, they should work together to run an effective filtration system and produce the highest quality dairy products.