John A. Lucey

John A. Lucey is a professor of food science at the University of Wisconsin, Madison, and the director of the Center for Dairy Research.

ARTICLES

The case for fortifying cheese

Overall, Americans do not suffer from nutrition deficiencies. But cheesemakers might find opportunities in niche markets. Certain bioactive peptides have potential benefits. They are worth watching.

August 8, 2014

Food processors look for natural cheese

It is estimated that 70% of all cheese used in processing channels is natural. The key varieties are Cheddar, mozzarella, cream cheese and hard Italian cheeses.

April 13, 2014

The cheese of the future

Cheese manufacturers and their suppliers will develop more pronounced flavors. They’ll use waterless mozzarella cookers and make cheeses entirely in their retail containers.

August 18, 2013

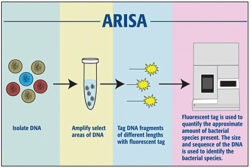

Technology is creating new dairy products

Advances in membrane technology, microbiological techniques and analytical testing help the dairy industry produce new products, improve processing efficiency and gain greater control over manufacturing processes.

April 14, 2013

The balancing act in making process cheese

When sodium salts are reduced in a cheese product, the pH and moisture content should be adjusted as well.

January 19, 2013

Make a better-tasting, low-fat Cheddar

Rather than calling them low-fat Cheddars, describe them as high in protein, much like Greek yogurt makers compare themselves to traditional yogurt.

October 9, 2012

View All Articles by John A. Lucey

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing