Home » automation in a dairy plant

Articles Tagged with ''automation in a dairy plant''

Grade-schoolers earn trophies at two tournaments.

Read More

Signode offers Endra Horizontal Strapping System

System adds flexibility and load stability to end-of-line packaging process.

April 3, 2024

Cheesemaker benefits from automation and inspection technology

Tasting, approving and signing every cheese batch to accompany these internal quality controls, several of their flagship processing plants now deploy the latest inspection and checkweighing technology from Fortress.

December 19, 2023

Standards for robot-based automation systems

Sanitary design book provides criteria for handling robotics in dairy plants.

August 30, 2023

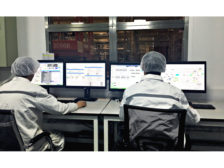

Dairy plants benefit from process automation

Dairy processing equipment market to reach $15.5B by 2029.

April 18, 2023

What to know before adding robotics or automation products

Craig Souser, president and CEO, York, Pa.-based JLS Automation. provides details about the safety of such products, plus a lot more.

February 23, 2023

Bako named BAK Food Equipment director for business development

Bako will spearhead the expansion of new customer accounts as well as foster the growth of BAK Food Equipment’s existing client relationships.

January 26, 2023

Festo celebrates 50 years in the U.S. market

Company hosted a special anniversary event at New York City's Gotham Hall.

October 21, 2022

Automation helps dairy processors optimize operations

The automation design process should begin before facility construction even begins.

September 30, 2021

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1681747050&width=275)