Home » CIP

Articles Tagged with ''CIP''

Zee Co. announces addition of Zee Dairy Division

Zee Dairy consists of experts in the dairy and sanitation industry, each one a pragmatic problem-solver with expertise at every level of dairy operations.

December 15, 2022

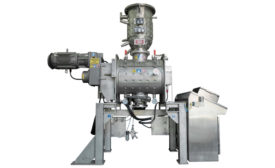

Dairy equipment cleaning: CIP vs. COP

It is essential that the intended method of cleaning and sanitizing is determined during the design phase of every project.

April 28, 2022

Selecting a spray device for clean-in-place equipment

Fixed spray devices, single-axis rotary sprays and multi-axis rotary sprays all offer certain advantages, disadvantages.

December 7, 2021

Water management practices in dairy processing plants

The best fluid-milk plants use about one-half gallon of water per gallon of milk processed. The least efficient plants use four times that amount.

April 10, 2012

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing