Home » dairy processors

Articles Tagged with ''dairy processors ''

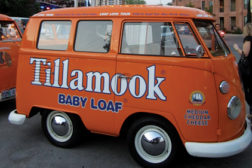

Tillamook: a look inside the plant

There are no secrets to making award-winning cheeses. Just buy the freshest milk and hire the best cheesemakers. Tillamook invites tourists to see the process from an observation deck inside the processing plant.

September 12, 2012

Tillamook: The little co-op that can

The little co-op that can Tillamook County Creamery Association is growing beyond its roots in the Pacific Northwest. Meet the dairy cooperative making award-winning premium cheeses that are among the top-selling brands.

September 10, 2012

Dairy digesters benefit supply chain, local community

In New York state, two dairy processing plants that turn waste into energy (biogas), have created enough renewable energy to heat about 2,600 typical homes in the Northeast for one year.

August 17, 2012

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing