3-A Sanitary Standards looks at reducing costs and the environmental impact of cleaning

Simple solutions to reducing water usage/costs while improving cleaning/sanitizing.

Photo courtesy of leolintang / iStock / Getty Images Plus

We live in a world with limited resources, especially fresh water, and it’s the lifeblood of cleaning systems in food and beverage processes. The 3-R’s of sustainability are Reduce, Re-use and Recycle. This discussion is going to focus on Reduce.

It’s a common misconception that sustainability costs money. However, the reality is exactly the opposite — Sustainability saves money. When cleaning equipment, every gallon of water that we can reduce is a gallon of water that we don’t need to pay for, heat, treat with chemicals, and pay to discharge.

If process equipment and cleaning systems are designed and programmed to focus on water reduction, process equipment can be cleaned faster, more effectively, and more efficiently using less water, chemicals, energy, and time.

So, let’s explore some key areas within cleaning systems that can save dairy processors time while also reducing water, chemicals, and energy.

Break the vortex

Due to the Earth’s rotation, vortexing occurs naturally in any process vessel as water drains. As the water drains. it forms a whirlpool at the outlet. As air is sucked into the center of the vortex, it backs up in the vessel and takes a long time to drain. Every gallon of water in the whirlpool is a gallon you have to pay for, discharge, heat, and treat with chemicals. Unfortunately, it also isn’t cleaning anything. The only water that cleans the vessel is the water in contact with the sidewalls.

The photos below illustrate this vortexing quite well. The photo on the left is in a tank cleaning at 40 GPM. The water running down the sidewalls is very effectively cleaning the tank with a simple vortex breaker at the outlet, and no excess water. The photo on the right is the same tank, same conditions, but with the vortex breaker removed. The water in that vortex is approximately 8 inches deep. Every drop has to be paid for, heated, treated with chemicals, and discharged to drain, and it’s not cleaning anything. And this simple tank took more than 2 minutes to drain, because it was sucking air through the vortex.

Why does this happen? Because vessels are all too often designed for processing when the tanks are full, and vortexing is not an issue. But all vessels should also be designed for cleaning as well, with effective and sanitary vortex breakers. The cost? Perhaps $300. The savings are enormous.

Photos courtesy of Sani-Matic.

Pulsing rinses/draining

When programming and running clean-in-place (CIP) systems, the focus tends to be on the wash steps: the time washed at temperature and chemical concentration. Very little emphasis is put on the rinses and especially the drain steps.

Rinses are much more effective if they are pulsed and allowed to drain completely. When vessels are rinsed continuously, the water tends to build in the bottom of the vessel, and any fats, oils, or light solids will float on the surface. When the vessel is ultimately drained, those residues remain on the surfaces.

Drain steps are often ignored because everyone is eager to get to the next step. Shorter steps get done faster, right? Well not quite. Testing was conducted on a CIP system comparing the post rinses by monitoring the conductivity of the caustic in the return line. In this testing, it was demonstrated that the vessel actually rinsed faster and more effectively than continuous rinsing, using much less water when the rinse water was pulsed and allowed to drain completely between pulses.

If you don’t believe it, test it. This doesn’t cost a penny to implement except a little time. Further, if a self-priming return pump or liquid ring return pump are implemented, the savings is even greater.

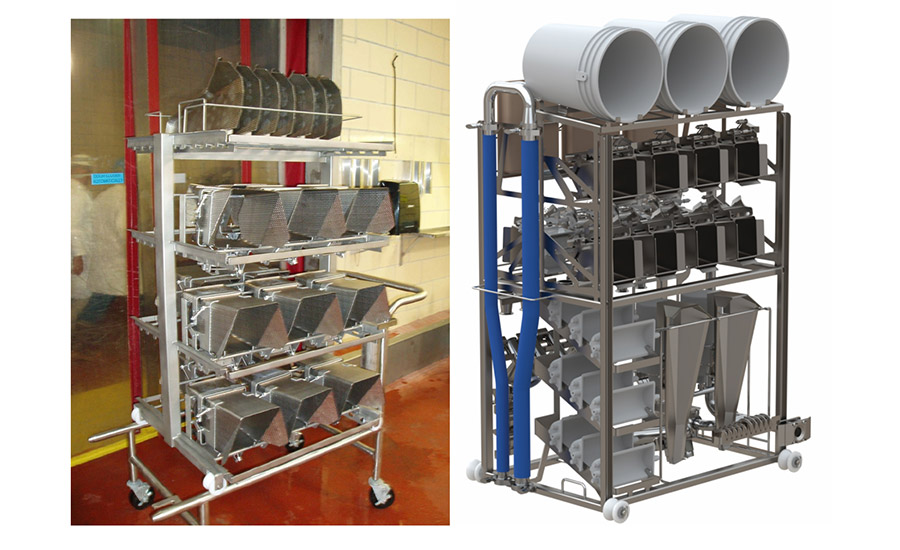

Cabinet washers versus COP tanks

How many adults take baths in the morning? I’ll venture to say not a single person reading this took a bath this morning — they took a shower. Why? Because it’s faster, uses less water, less energy, less soap, and it gets you cleaner than sitting in dirty bath water. And when you climb out of the bath, you still have soap scum from the water. So why do we continue to give our process equipment baths instead of showers?

A Cabinet Washer can be much more effective at cleaning and sanitizing equipment automatically and faster, like a dishwasher on steroids. The amount of water, chemicals, and energy are at least an order of magnitude less that the same cleaning cycle in a COP tank. A typical COP tank holds 200 gallons of water, while a typical Cabinet Washer holds perhaps 10 to 12 gallons.

A Cabinet Washer holds the components to be cleaned on a rack, much like a dishwasher, with a location designated for the cups, bowls, plates, and flatware. The cycle can be validated, every cleaning cycle can be documented, and the clean parts can be rolled on the clean rack back to the process equipment for re-assembly, with minimal risk of recontamination. How can you validate a COP cleaning cycle and get the parts re-installed without risking decontamination?

Photos courtesy of Sani-Matic.

It costs a little more and takes more effort to implement these simple solutions, but they will improve your dairy plant’s cleaning and sanitizing while reducing the cost of water, energy, chemicals, and lost production time. You buy equipment once, but you pay for it for 30 years.

Sustainability doesn’t cost — it pays!

* Gabe Miller has 30 years of experience in cleaning and sanitizing equipment and is the owner of Process Innovation – Food Safety LLC, which provides sanitary design guidance, training, sanitation audits, and 3-A CCE Third Party Verification (TPV) inspections. www.pi-fs.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!