Packaging upgrades boost dairy product marketing

Evolving technologies are enabling dairy processors to leverage packages with vibrant graphics, while enhancing product safety and sustainability.

Photo courtesy of ShotShare via www.gettyimages.com

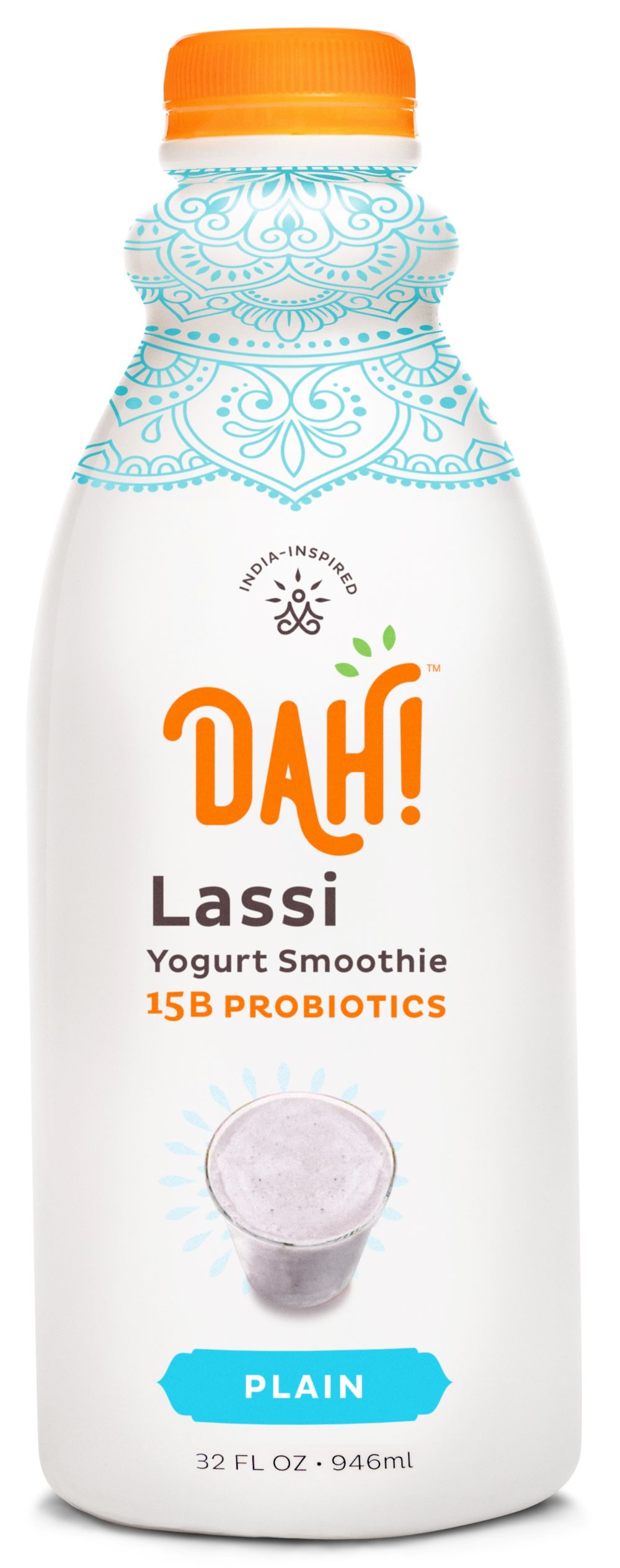

Packaging is becoming an increasingly potent dairy merchandising vehicle. Enhancements to labeling, shrink wrap, and printing equipment are resulting in the development of visually appealing containers with recyclable films and sleeves that are tamper-evident and that help extend a product’s shelf life.

“The right print finishing technologies can help brands perform better, stand out on shelf, and create an elevated consumer experience, all while delivering consistent operational performance,” says Travis Klug, marketing manager for dairy at Amcor Flexibles North America, a Buffalo Grove, Ill.-based packaging supplier.

He notes the importance of a product’s first impression, particularly because of the huge amount of competition for share of stomach. “A product might taste amazing or be the best solution amongst the competition, but unless the consumer’s attention is captured at shelf, they will not purchase and experience the product,” Klug explains.

Indeed, it is crucial that dairy processors “get creative” with containers and label designs, says Eddie Kingston, quality manager for Deer Park, N.Y.-based Overnight Labels.

“Shrink sleeves and labels allow for eye-catching specialty effects and finishes and helps to distinguish the product from the rest,” he states, adding that specialty sleeves which block light can keep dairy products fresher longer.

Processors that leverage functional labeling are then able to devote greater attention to other bottling process needs, notes Tony Cook, CEO, and owner of Comstock Park, Mich.-based Great Lakes Label.

“Conversely, ineffective labeling can start and stop the production line so often that the processor can't gain any efficiency or at least identify opportunities for efficiency gains in any other area of the line,” he states.

Plan for future production

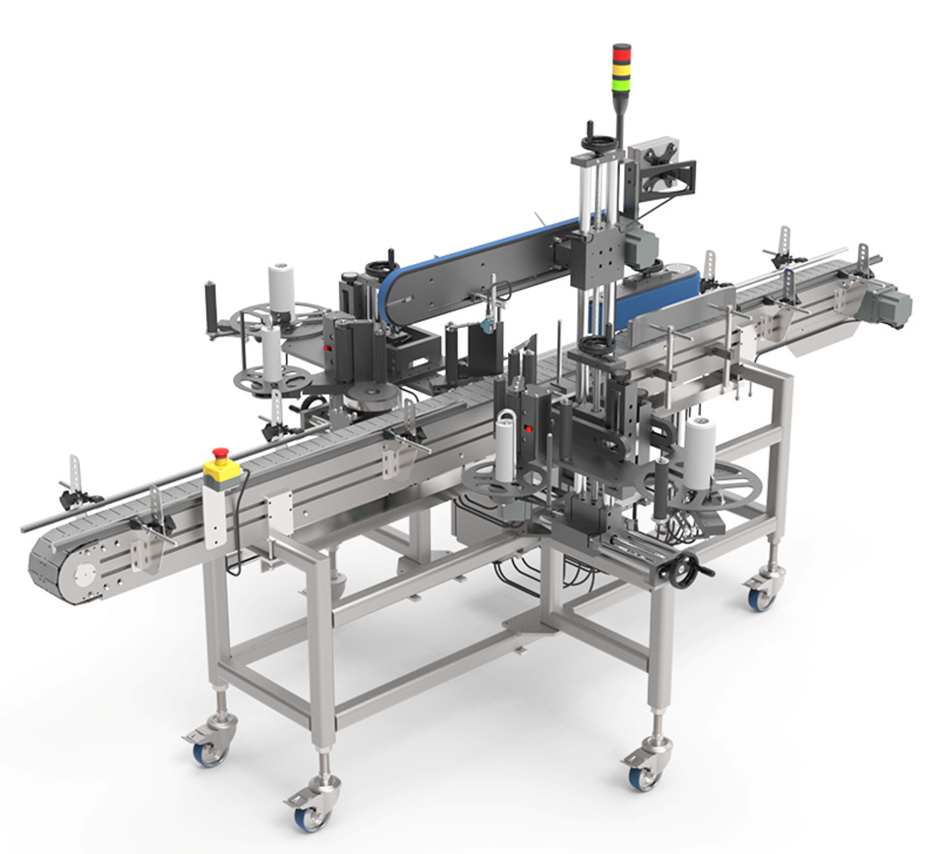

Operators, meanwhile, should consider current and upcoming production rates when considering packaging technologies, Cook suggests. Some systems, for instance, enable users to enhance productivity with zero downtime by allowing processors to affix additional labeling heads to devices during production. The labeling head – or labeling applicator – attaches labels to the container or product.

“Processors should purchase equipment that can run must faster than they expect to be running so that the labeler isn’t maxed out on its capabilities,” adds Justin Slarks, director of marketing for Sleeve Seal, a Little Rock, Ark.-based provider of shrink labeling solutions. “This minimizes equipment wear and will ensure consistent performance and efficiencies.”

The best packaging film, adhesives, and laminates, meanwhile, will differ in accordance with each operator’s unique production and merchandising environments, Kingston says. Variables include whether products are frozen or refrigerated, and if the items sell at retail outlets or kept in warehouses.

The need to operate in a hot, cold, or wet production environment also can affect technology selection, according to David Holliday, director of marketing communications for Covington, Ky.-based ProMach Inc.’s ID Technology and EPI brands of labeling, coding, and marking equipment. It is important, for instance, that equipment functions properly in areas where production lines undergo washdowns for sanitation.

Incorporating the proper shrink sleeve equipment will lead to operating efficiencies as well, Holliday notes. A shrink sleeve, a type of film packaging, usually consisting of polyester or plastic, which slides over the product container and undergoes heating to conform to the contours of the container. The process enables producers to display graphics that wrap around the package with zero creasing.

The 360-degree benefits of this packaging type is growing exponentially. In fact, Dublin, Ireland-based Research and Markets forecasts that the global stretch sleeve and shrink sleeve label market will have a 5.6% compound annual growth rate (CAGR) from 2021 to 2026, with revenues increasing from $14.4 billion to $18.9 billion.

“Shrink sleeves are widely used as they offer 360 printing facilities, tamper-evident features and conform to any intricate shape of the end product,” Research and Markets states. “Additionally, it provides more space for information.”

Greater demand for polymer films, and interest in leveraging more suitable, durable and cost-effective packaging, is further driving the stretch sleeve and shrink sleeve markets, states New York-based Polaris Market Research. The firm adds that such film “prevents different kinds of malpractices like adulteration and reuse of containers that are supposed to be discarded.”

Focus on system flexibility

In addition, the use of more versatile shrink sleeve equipment is enabling product manufacturers to adapt quickly to market trends and changes in consumer preferences, says Ed Farley, product line manager for ProMach’s Axon brand of shrink sleeve applicators, stretch sleeve applicators, tamper-evident band applicators, and heat shrink tunnels.

“They offer a cost-effective way to accommodate short runs and label design changes on short notice,” he explains. “An effective, dependable solution will boost packaging operations by eliminating inefficiencies in the sleeving process, such as film splicing, and errors in sleeve application that can lead to costly planned and unplanned machine downtime.”

Indeed, degree of productivity is a key determinant when selecting shrink sleeve technologies, Farley adds.

“It is important that processors look closely look at how efficient the system is in splicing film and applying bands and full and partial sleeves,” he states. “Due to nuances in film application, success comes down to how simple and easy it is to keep the system running.”

A host of additional variables also require consideration when selecting printing equipment, says Marc Sorem, director of product development for TC Transcontinental, a Montreal-based flexible packaging supplier. Elements include whether the processor will utilize surface or reverse printing; the number of colors that will be on designs; color combinations; print complexity; and if the print technology will achieve the shelf look sought for products, he states.

“With today’s need to stand out amongst the crowd, many processors are opting for matte and gloss print combinations on the same package,” Sorem notes.

Substrates and run length should factor into selection decisions as well, adds Hank Welter, TC Transcontinental vice president of manufacturing excellence. He says, for instance, that “digital print systems are optimal for very short runs as the costs do not scale well and can limit substrate choices.”

Access to machine touchpoints essential

Along with leveraging the most functional machinery, it crucial that processors have workers who can expertly implement, operate and maintain the technologies in order to sustain high performance levels, says Jay Sinclair, director of sales, Eastern region, for Minneapolis-based Engage Technologies Corp., parent company of Squid Ink, a manufacturer of coding and marking systems for product identification and traceability.

“Proper installation, set-up, and long-term maintenance are essential to ensuring the success of any coding and marking application,” he states. “Operators should be trained properly and given adequate supplies for the system. Having personnel, such as line operators, production supervisors and maintenance people available during the installation for training will also result in a successful equipment solution long term.”

In addition, designs that provide easy access to key machine touchpoints will make it simpler for processors to resolve the inevitable unplanned downtime due to film and product jams, Farley says. Indeed, the location and position of the film supply relative to the machine operator, and the ease in performing reel changeovers, are key factors when analyzing systems, he notes.

“The trick is to clear a jam and get the machine back up and running as quickly as possible,” Farley states.

Partnering with technology developers that have experience in providing designs that support a processor’s specific dairy application will further enhance productivity, he says.

“Choose a partner who has been there before; who has a list of references in the industry; and the service and support capabilities to prevent disruption and quickly correct unplanned downtime,” Farley says.

Working with suppliers that have a strong comprehension of shrink labels, and the technologies to support processors’ production goals, also is critical for creating distinct packaging that better catches shopper attention on crowded retail shelves, Slarks states.

“It is very important to understand the labeler’s capabilities as while there are new printing and label material options, not all labelers are ready to apply labels at the necessary speed,” he notes.

Equipment manufacturers that provide staff training and offer devices that do not require downtime for label roll changes will further improving productivity, which “keeps everyone happy,” Holliday adds.

Yet, processors that pinpoint technologies with the optimal functionality for their operations still must ensure that the equipment is affordable and can fit on the production lines if they are to leverage the devices, Cook states. He reveals that producers might solve budget concerns by purchasing modular label systems with the capacity to only support current production needs but can easily expand to address future growth. Operators, meanwhile, can better manage a system’s footprint by incorporating devices that enable the mounting of the labeling head to an existing conveyor, Cook says.

“While labeling machine design is quite mature, the latest generations of equipment are becoming more intelligent and easier to use, making it easier to get the best results for labeling quality and productivity,” Holliday states. “The right labeling equipment, combined with effective operator and maintenance training, keeps the packaging operation running with peak performance.”

Printing technologies, meanwhile, are continuing to improve in fidelity and quality across varying substrates and equipment, Welter notes. The addition of scan-nable codes to packages is enabling processors to provide updates on products throughout the life cycle.

Welter points out that going forward, processors will use such codes to identify packaging content and aid in recycling and other post-use processes – with new innovations in packaging technologies at the forefront.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!