Suppliers put a spotlight on new automation and robotics equipment.

Baumer

Benchmark

BluePrint Automation

Burkert Fluid Controls

FlexLink

Integrated Packaging Machinery (IPM)

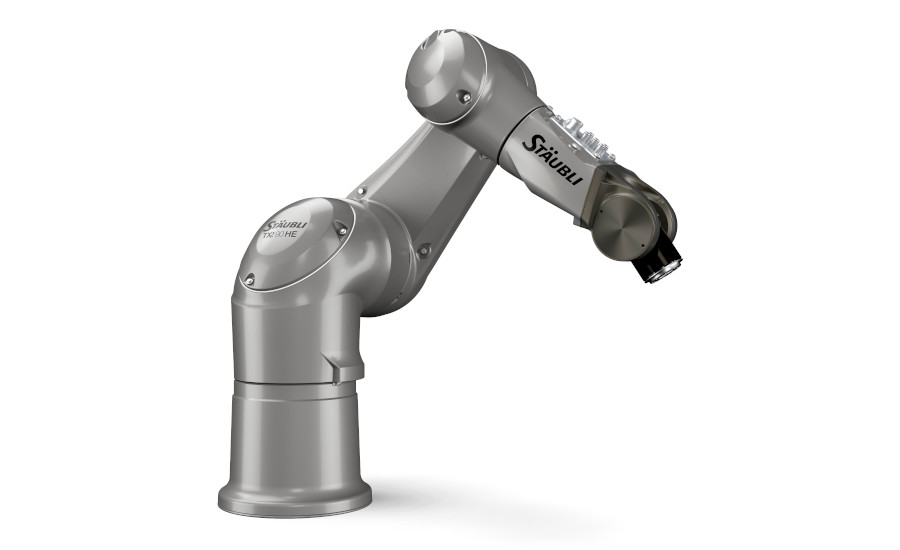

Stäubli

Texwrap

CONDUCTIVITY MEASUREMENT

Baumer says its PAC50 process sensor sets new standards in measuring conductivity and is ideal for small-sized production installations. It offers high performance tightly packed in a very compact design. Thus, the sensor is ideal for use in small production facilities — in general industrial applications, but especially in the food and pharmaceutical industries. Its high temperature stability, up to 140 degrees Celsius, allows for permanent and reliable use even in sterilization-in-place systems.

800-937-9336; www.baumer.com

FEEDER SYSTEM

Benchmark's InFlight AC feeder uses autonomous carts to receive randomly spaced product and times it to the flights of a packaging machine. Instead of traveling on a conveyor belt, each product is received individually on a cart. This provides a tremendous advantage with regard to sanitation, the company says. The removable carts make cleaning a snap. Carts queue on the underside of the system and move to the top to receive each product on a one-to-one basis and are ideal for fragile and irregularly-shaped products. Products then travel to the discharge end of the feeder for delivery.

706-208-0814; www.benchmarkautomation.net

WRAPAROUND CASE PACKER

The Wraparound 100 case packer from BluePrint Automation automatically erects, loads and closes wraparound cases, trays, tray-lid combinations and regular-slotted-carton cases. With its hygienic design, the Wraparound 100 is built for food applications and has a fast and tool-free changeover, making it ideal for packing multiple products on the same line, BluePrint Automation notes. Modular in design, it accommodates a variety of standard product-handling systems and is ideal for cartons of dairy products.

804-520-5400; www.blueprintautomation.com

STREAMLINED INTEGRATION

Burkert Fluid Controls is integrating process valves, sensors and controllers via Ethernet IP and IO-Link using add-on profiles and add-on instructions for Allen Bradley/Rockwell Automation PLCs, which allows for streamlined integration and simpler setup. The valve island Type 8652 AirLINE and the field device Type 8653 AirLINE Field provide easy commissioning and maintenance, as well as minimized process risk, regardless of whether placed into the control cabinet or directly into the process environment, the company says. Thanks to a wide range of communication options, they are also future-proof in times of Industry 4.0. In addition, integration into the Burkert Efficient Device Integration Platform is possible.

704-504-4440; www.burkert-usa.com

WIDE-BELT SOLUTION

FlexLink’s wide-belt solution WLX in stainless steel is safe and clean, and it reduces the total cost of ownership. It adheres to European Hygienic Equipment Design Group and 3A Sanitary Standards design guidelines and addresses the higher hygienic requirements associated with primary and secondary packaging. WLX sets new standards for cleaning results and cleaning process time in the food industry, FlexLink says. The modular belt conveyor is suitable for all industries, including dairy, where the requirements for hygiene and accessibility are particularly high, and the system ensures trouble-free operation and a long service life.

610-973-8200; www.flexlink.com/en

CABLE MANAGEMENT TURRET

The patented EOA cable management turret from Integrated Packaging Machinery (IPM) reduces maintenance and extends the life of robotic palletizers. The end of the arm is where the bending radius of the air, electrical, vacuum and ethernet cables and hoses are most acute — and where the pick-and-place functions are most frequent. By preventing cable fatigue at the EOAT, the IPM cable management turret assembly can allow for a smaller palletizer footprint, the company notes. It’s not unusual for a robotic palletizer to see 3,000 or more cycles per shift. Each time a cable bends or flexes, its copper conductors and shields are stressed. This assembly significantly reduces cable and hose fatigue and optimizes packaging system uptime.

616-293-3411; www.callipm.com

ADVANCED RANGE ROBOTIC ARM

The advanced range of HE robotic arms from Stäubli are popular in food processing, due to a unique hygienic design that eliminates the risk of contamination while optimizing efficiency and productivity. These and other capabilities make them ideal for many applications in cheese and other dairy production applications such as unwrapped food handling, waterjet cutting, slicing, molding and demolding, turning, spraying, loading and unloading, as well as in packaging and palletizing. They are also well-equipped to withstand the intensive washdown applications required to ensure regulatory compliance, Stäubli says.

864-433-1980; www.staubli.com/us/en/robotics/industries/food.html

SHRINK WRAPPING SYSTEM

Texwrap’s intermittent motion Tekkra 200 Series sideload bundler comes with a modular design that offers dairy companies, co-packers and other customers the opportunity to customize their machines for maximum productivity based on the layout of their plant. With a speed of up to 20 packs per minute, the Tekkra 200 is ideal for numerous dairy-bundling packaging styles, including bottles, cans, cartons, tubs, pails and other multi-packed products, the company says. Features on the Tekkra 200 Series include an Allen Bradley PLC/HMI interface — which ensures user-friendly, reliable operation — and servo-driven main ram for product control and simplified changeovers.

800-886-7421; www.texwrap.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!