New packaging, inspection and conveying equipment from dairy industry suppliers

SERVO-DRIVEN PACKAGING MACHINE

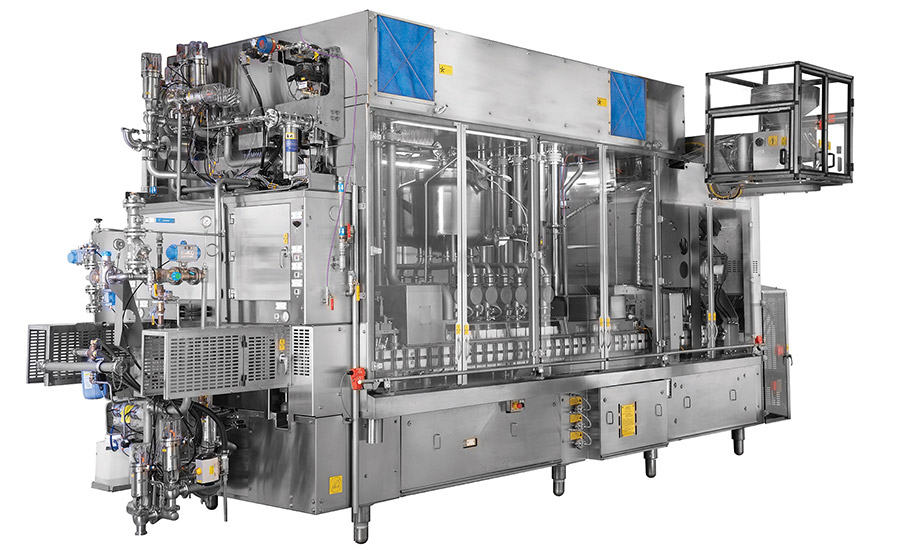

Evergreen Packaging Equipment says it introduced a servo-driven EH-84 gable-top packaging machine. Designed to meet the needs of the dairy, juice and liquid food markets, the EH-84 can handle fill volumes from 40 ounces to 2 liters at speeds up to 8,400 cartons per hour. Allen-Bradley PLC controls and servo-driven technology provide repeatable package performance and automatically control fill volumes and profiles based on product and carton size. Infinite fill capability allows for less downtime with quick and easy changes in carton size or product. The infeed’s ergonomic design provides operator comfort and ease of loading.

319-399-3294; www.EvergreenPackaging.com/EH-84

CONVEYORS WITH MANUAL LIFT GATES

Multi-Conveyor says it recently built a series of powered plastic-chain conveyors that incorporate manual lift gates for operator access and pneumatic stop/clamp control for seamless merge. The overall project merges two lines fed from two existing case packers down to a single lane prior to a customer’s case sealer and ultimate palletizer. Slightly inclined, offset conveyors incorporate manual lift-gate assemblies for operator access within a confined production area. The designated priority line conveys the cases to a right-angle transfer, maintaining product orientation. Product ultimately single files to an existing case sealer, all controlled by sensors and metering devices strategically placed by Multi-Conveyor.

800-236-7960; www.multi-conveyor.com

SEAL INTEGRITY INSPECTION SENSOR

Teledyne TapTone released a new seal integrity tester (SIT) designed to inspect cups inside the cup filler. The SIT has a patented design that consists of multiple sensors mounted inside the cup-filling system that inspect each cup by compressing the sensor head to the foil lid of the cup at full production machine speeds. The system can detect bad seals caused by product across the seal area during filling, deformed or damaged foil lids that cannot make a good seal, and weak seals resulting from a variety of issues. The SIT sensor incorporates an easy-to-use PC user interface, graphically displaying “good” non-leaking cups in green and “bad” leaking cups in red.

508-563-1000; www.taptone.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!