advertisement

Ensuring Matching Label & Caps Ice Cream Manufacturers Turn to Vision

Ice cream is a popular product in the dairy industry. With varied ingredients from nuts, flavors and fruits mixed in, product recalls are a very real danger. Manufacturing plants produce multiple varieties of ice cream, often on the same production lines, which increases the risk of a flavor of ice cream going into the wrong tub. At the very least, this could lead to a disappointed customer, but when allergens enter the equation, the results could be significantly worse. Add to this overall increased production speeds, and it begins to look like a serious problem waiting to happen.

Major Manufacturers Take Initiative

Rather than waiting for something to go wrong, several ice cream manufacturers made the decision to implement preventive measures. They approached multiple vision equipment manufacturers, including METTLER TOLEDO, to evaluate the performance capabilities of vision inspection systems on their oval ice cream containers.

After evaluating the product sample, METTLER TOLEDO suggested a flexible vision system and offered to install a demo system in the plant for a trial. It did not take long for the manufacturer to realize how useful the system was, and by the time the trial period was up the decision was made to install vision inspection systems on all production lines in the facility.

With our expertise in inspecting ice cream containers, we are able to offer the best solution, whether it be for round or oriented containers. For a new manufacturer of round ice cream tubs, we set up a complete 360 degree system. Once again, after a demonstration of the system in action, the manufacturer purchased a system as part of a pilot vision inspection program, and quickly ordered additional systems for the rest of their production lines. This has resulted in other ice cream manufacturers approaching METTLER TOLEDO for their inspection needs, and the systems are being considered for world-wide deployment in all production facilities for the respective brand owners.

What Do The Systems Do?

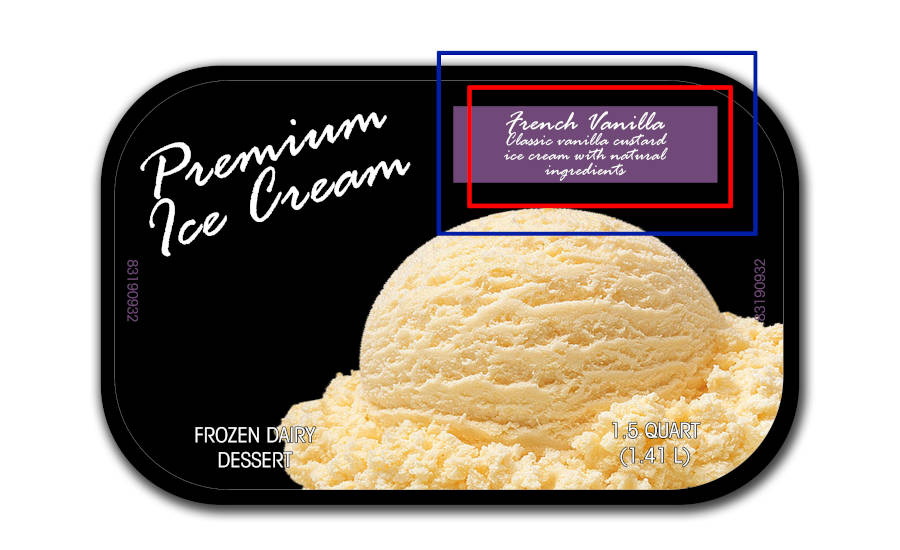

For each variety of ice cream, the system looks for a particular graphical element that is unique to that flavor – usually part of the flavor name. This is accomplished by creating a search area in the location of the name. The size of the search area is dependent on the size of the graphical element and where it may appear. These settings are specific to each part, as the text for one variety may be larger or smaller than the text on another variety. The system does not need to identify which variety of ice cream is currently running; it merely needs to know whether or not the specific graphical element it is looking for is present. If the system cannot locate the element, it is removed from the production line.

METTLER TOLEDO Vision Inspection systems come with standard side cameras and offer an additional top-down camera to perform the same graphical identification inspection on the lid to verify the lid and tub match. More accurately, the product profile will contain two separate inspections looking for the same graphical element in different locations, and if both inspections are successful, the system knows the lid and tub match. Should either of the components be incorrect, the system will reject the product off the line, and in the event of multiple failed products, the system will alert operators.

Other Capabilities

While the systems in this case are only needed to perform graphical identification, there are other capabilities each system is capable of performing with only a few minor changes to the configuration. The system is capable of adding inspections to ensure product lids are correctly seated on tub and free of defects, or that the tamper band is present; and the flexible system has an expandable design that allows these inspections to be added later.

Ongoing Development

Since installation, the system has prevented multiple mislabeling scenarios – the cost of the recall that could have resulted has more than made the cost of the system worthwhile. METTLER TOLEDO is continuing to support their system installations, with part replacement plans and other service and training offerings to educate new operators and help personnel take full ownership of their vision programs.

For more information, visit www.mt.com/ci-vision

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!