New processing equipment offerings increase efficiency and reduce costs

HIGH-SPEED DISPERSER

Admix’s DynaShear is an inline high-speed disperser with a rotor/stator design that ensures 100% of ingredients are fully utilized rather than filtering them out due to inadequate conventional mixing. The product passes through the DynaShear, which is installed on the outlet of a mix tank. The disperser then instantly completes the desired mixing of stabilizers, gums, whey/plant proteins, sweeteners and milk/cocoa powders. Admix said the DynaShear reduces batch times and air entrainment and eliminates clogged strainers and heat exchanger burn-on. Select configurations are available as quick-ship items.

800-466-2369; www.admix.com

HEAT EXCHANGER PLATES

AGC Heat Transfer Inc. (AGC) announced the launch of three new heat exchanger plates: the Pro8, the Double5Plus (AGC’s air gap plate) and the Pro5Snap. The company’s entire plate collection consists of plates made specifically for the sanitary food and beverage market. AGC said its new products offer a range of features, from the bright annealed finish on 316 stainless steel to the enlarged inlets providing lower pressure drops and better cleaning during clean-in-place regimens.

800-825-8820; www.agcheattransfer.com

IN-TANK MIXER

Ampco Pumps Co.’s newest addition is a JET-shear in-tank mixer. The company said its applied products group is rapidly growing its product line, and the JET-shear in-tank mixer is the latest addition. This system is used to hydrate, dissolve, homogenize, disperse and emulsify products consistently and efficiently. The multiple interchangeable stainless-steel work heads are designed for 3A and clean-in-place operations. Custom shaft lengths, varying motor styles and mounting options are available.

414-643-1852; www.ampcopumps.com/jet-shear/

SANITARY TUMBLE BLENDER

Charles Ross & Son Co. said the Ross VCB-0.25 tumble blender is uniquely suited for specialty blends with extremely minor active components and additives. Ideal for processing high-value and delicate applications, the tumble blender is often provided in a sanitary all-stainless-steel construction and imparts gentle agitation. Options for process optimization include vacuum design, heating jacket, intensifier bar for deagglomerating clumps and custom PLC controls. The vessel’s characteristic v-shaped geometry facilitates 100% product discharge. Ross tumble blenders are available across a full range of working capacities from 1/4 cubic foot to 100 cubic feet.

800-243-7677; www.mixers.com

CONTACT MONITORING SYSTEM

Coperion GmbH said its RotorCheck 5.0 contact monitoring system for rotary valves is the ideal technology to register, evaluate and report unwanted contact between the rotor and housing to prevent metallic abrasion, and thus, potential contamination of the product being conveyed or transferred. Food applications for a variety of powders, including those with a high number of cleaning cycles such as dairy, can particularly benefit from this instrumentation. The separation of measured value logging and evaluation electronics has advantages in terms of operation and maintenance, while the redeveloped control system provides advanced options for event diagnosis and communication to host systems.

785-825-1611; www.coperion.com

CHEESE SHREDDER

Deville Technologies is a client-centric company supplying solution-based manufacturing technology for the food processing industry. Deville’s ultra-hygienic FS40 industrial cheese shredder is accepted by the USDA and the Wisconsin Department of Agriculture, Trade and Consumer Protection. It provides large and small manufacturers alike with the ability to produce a variety of cuts without the need to pre-cube cheese blocks, thereby maximizing productivity and minimizing labor. Deville also offers conveying, handling and dispensing solutions. Deville said cutting-edge technology — coupled with traditional craftsmanship, quality materials and intelligent, hygienic principles — allows it to deliver solutions that deliver high performance with low maintenance.

866-404-4545; www.devilletechnologies.com

CHEESE-CUTTING TECHNOLOGY

Coprodev has been designing and building cheese-cutting technology exclusively for the 640- and 40-pound industry since 1989. Its entry system for cutting 10-pound loafs is its MACH-I ultrasonic cutter, which delivers 60 to 80 portions per minute. An additional cutter such as the 40-pound PN20 primary cutter can be added later for full automation. Coprodev’s speciality is its MACH-II 640-pound high-throughput cutting technology, which produces up to 220 portions per minute. Coprodev said simple, robust and smart technology translates into high yield: The payback period on cheese savings alone is less than two years (based on a single-shift operation).

450-449-3350; www.coprodev.com

COMBINED SHREDDER AND DEPOSITOR

Reiser said the Vemag cheese shredder and depositor brings a new level of portioning accuracy and waste control to cheese-topping lines. The Vemag integrates precise cheese portioning, shredding and depositing into a single process, eliminating the need for a separate shredder, transfers or excess handling. The system easily processes all types of cheese, including high-moisture mozzarella cheese, while eliminating the need for starch or cellulose fillers. It greatly reduces cheese waste and virtually eliminates recirculated shreds and the resulting cheese dust. This solution is ideal for dispensing precise portions of shredded cheese onto conveyed pizza and prepared meals, improving the product’s appearance and uniformity. The offering is available in various models and hopper capacities to meet any production requirements.

781-821-1290; www.reiser.com

LEVELING FEET

Koss Industrial’s stainless-steel equipment leveling feet are now 3-A Symbol authorized in all sizes. The feet help equipment run at maximum efficiency and eliminate stress points due to imbalance. Koss said its feet are the premier standard for U.S.-manufactured leveling feet. The feet easily weld to a tube or pipe, come in long or short lengths and fit a variety of common tube and pipe sizes (from 1 to 6 inches). Custom sizes are available, as are ball or weld toe options. The feet have load weight options of 500 to 20,000-plus pounds per foot. The feet are manufactured using 304 stainless steel, sealed with O-ring elastomers, have no exposed threads and are exterior polished to a No. 4 dairy finish (25-32 Ra).

800-844-6261; www.kossindustrial.com

CENTRIFUGAL PUMP

GEA Group added energy-efficient and hygienic GEA Hilge TP centrifugal pumps to its Smartpump line. These robust pumps are available in 11 different sizes, are optimally configured for different applications and use only two sizes of mechanical seals for the whole range. GEA said low-flow velocities and gentle discharge of media through the spiral housing enable extremely gentle product handling. The pumps offer easy maintenance, with a front-loaded seal and a design fine-tuned for each task.

415-272-8431; http://video.gea.com/gea-hilge-tptps-hygienic-pump

ANGLE SEAT VALVE

Emerson US introduced the ASCO Series 290FB stainless-steel angle seat valve for fluid control. The valve is a rugged high-flow valve providing up to 60% higher flow than competing designs and up to five times longer life than conventional ball valves. The 290FB series is able to meet the most demanding clean-in-place (CIP) applications, tolerating media such as hot water, acid, soda and hydrogen peroxide. Additionally, Emerson said the 290FB series is designed to comply with FDA CFR21 and (EC) 1935-2004 regulations for auxiliary fluids, making it an ideal choice for dairy CIP systems.

973-966-2000; https://www.emerson.com/en-us/catalog/asco-290

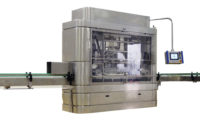

COST-REDUCING PROCESSORS

MicroThermics said it is celebrating 30 years of high-temperature/short-time (HTST), ultra-high-temperature (UHT) and aseptic innovation. MicroThermics’ newest lab processors build efficiencies and reduce costs. The company’s 30th anniversary-edition steam injection and indirect UHT/HTST processors are easy to use, with features such as extensive centralized touch-screen controls, set-up guides, recipes to store frequently used processes, integrated homogenizers, customizable processes, extensive filling capabilities (including an available aseptic laboratory filler) and more.

919-878-8045; www.microthermics.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!