Fogg Filler adds 3D printing lab

The lab is equipped with 10 printers that vary in capabilities.

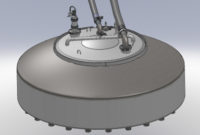

Fogg Filler, a Holland, Mich.-based specialist in the design and manufacture of rotary filling systems for the liquids industry, said it added a 3D printing lab. The printing lab is equipped with 10 printers that vary in capabilities.

The machines range in size, with the largest having the capability to print parts with 40-inch by 40-inch dimensions. These printers can print with a wide range of materials, the company said, including rubber, nylon, PETG, polycarbonate, ABS, PLA and IGUS. This range of materials makes it possible for many different departments to use these machines.

Before installing the printers, if Fogg was to make a back pocket (the part of the machine that holds bottles in place as they are filled) to test for a particular customer's bottle, the engineers would have to draw it up, and the machine shop would have to program the machines before machining the part on the router out of stainless steel, Fogg Filler noted. With the new 3D printers, the engineer simply draws up the part and inputs the information; a prototype then prints within hours in a cheaper material. The time savings is significant, allowing the company to greatly reduce lead times on custom parts.

Fogg said it continues to improve technology and provide the highest level of reliability for production lines. To discuss a particular application or learn about the company’s full line of filling and capping machines and accessories, contact Fogg Filler’s sales team at 616-786-FOGG or www.foggfiller.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!