Improve nonstandardized frozen desserts

The creation of ice cream-like functionalities and sensory appeal involves new challenges on multiple fronts

Ice cream formulation and processing have historically complied with the provisions of the U.S Standards of Identity (SOI) for Frozen Desserts with regard to composition, weight and, specifically, allowable ingredients. Such constraints limit the achievement of classical ice cream processing and sensory properties in products responsive to the marketplace realities of ever-changing consumer attitudes and preferences — whether these be health-, social- or cost-related. As a result, a growing number of products fall outside of the SOI provisions in one or more ways; they are referred to as “non-standardized frozen desserts” (NSFD).

Since NSFD do not conform to the SOI, they cannot be identified by authorized terms such as “ice cream,” “frozen custard,” “French ice cream,” “French custard ice cream” and “sherbet.” Thus, the common practice is to refer to NSFD either as “frozen dairy desserts” (FDD) if the product contains milk ingredient(s) or as “non-dairy frozen desserts” (NDFD).

As with standardized products, the laws of chemistry and physics (aka “Mother Nature’s rules”) need to be properly applied. Technical burdens in any given formulation, standardized or not, dairy-based or not, will exist.

However, basic ice cream science and technology remain keys to success. Formulation needs, specifics and demands on any NSFD product may require varying approaches, which may be both novel and technologically challenging. As a product deviates further from the SOI, challenges arise, making it increasingly daunting to create and maintain desirable behavior (i.e., flow, whipabilty, scoopabilty, melt properties) and overall sensory appeal (i.e., body, texture, flavor delivery).

Major expected departures of NSFD products (both dairy- and plant-based) from the SOI requirements may include one or a combination of the following, with potential effects and guidelines noted:

1. Low level of milk solids not fat (MSNF) can cause weak, crumbly body and accelerated growth of ice crystals and air bubbles across the whole supply chain. The effect is related to a reduction in freeze concentration effects that increase water and air bubble mobility in the unfrozen portion of the mix.

This can be managed via freezing point control and the use of ingredients that control the stability of small ice crystals and air bubbles via increased viscosity and other rheological effects in the unfrozen portion. Ingredients may include high-performance stabilizers such as microcrystalline cellulose and propylene glycol esters, and the bulking ingredient maltodextrin (particularly, digestion-resistant varieties with more complex structures).

Rheology management can also be accomplished via protein effects caused by high processing temperatures of mixes and/or dairy ingredients. Low draw temperatures, rapid hardening and minimized exposure to heat shock and high post-hardening temperatures are also important.

2. A high proportion of whey solids in the total MSNF component (i.e., >25%) can introduce off-flavor, which can be minimized by careful selection and management of the whey ingredient. Negative effects on freezing point depression can increase ice crystal and air bubble size and stability.

At high levels, the replacement of casein by whey protein can interfere with desirable effects on fat agglomeration (e.g., whipability, stiffness and dryness at the freezer, creaminess and meltdown behavior). This can be managed by keeping the level of micellular casein higher than 50% of the total milk protein.

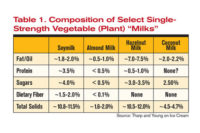

3. Use of non-dairy proteins can have similar effects to whey proteins. The functionality of micellular casein is critical for fat agglomeration, a key contributor to ice cream structure. Other proteins are likely to interfere with fat agglomeration, especially at high use rates.

As larger (and more complex) proteins are used, differing and more complex interactions with fat/oils and naturally occurring and added flavors, as well as interference with the behavior of liquid water, can occur. Negative effects can be minimized by careful selection of the amount and type of non-dairy proteins used. Careful consideration of the mix environment (e.g., pH) into which the selected protein(s) is (are) used is critical to ultimate body, texture and flavor delivery.

4. Replacing dairy fat with non-dairy fat can negatively influence eating quality (e.g., greasiness, waxiness, flavor effects), whipability and air bubble size, which can be minimized by selecting alternate fats with flavor and melting properties similar to those of milk fat. There can be exceptions, since the chemistry and physics of milk fat alternatives in context in any formulation can be highly variable.

5. Sweetener changes — for example, the use of alternative sweetness sources such as sugar alcohols, high-intensity sweeteners and non-traditional sugars and/or a reduction in sugar levels — also have an impact. Effects can include unnatural sweetness and atypical freezing points. So select alternative sweeteners with desirable sweetness profiles and manage the amounts and types to keep the freezing point and freezing profile close to that of conventionally sweetened products.

6. High overrun — less than the minimum weight per gallon required by the SOI (4.5 and 4.0 pounds for ice cream and fat-reduced ice cream, respectively) — can reduce the perception of richness and creaminess and cause loss of air cell strength and stability (shrinkage) and undesirable “scooping” properties. Minimize those effects by encouraging the development and stability of small air bubbles via the selection of emulsifiers. For non-dairy products, limitations to overrun are a bit more complex.

The creation of ice cream-like functionalities and sensory appeal in NSFD involves new challenges on multiple fronts. Nevertheless, the process requires application of essentially the same science and technology as applied to any frozen dessert. Isn’t that nice to know?

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!