The latest filtration equipment highlights sanitary, efficiency aspects

GEA

Microdyn-Nadir US

Pall Corp.

SPX Flow

Inopor

Tetra Pak Filtration Solutions

Pentair

Alpma

ProSpect Analytical

Powder-Solutions

Blister-free sanitary membranes

In conjunction with General Electric (GE), GEA offers GE Blister Free membranes. These reverse osmosis (RO) membranes have the potential to significantly reduce costs for dairy processing plants, according to the company. RO membranes are especially susceptible to blistering because of the high pressures experienced during the process. The problem can also occur in nanofiltration and ultrafiltration membranes when used in some applications.

715-245-8604; www.gea.com

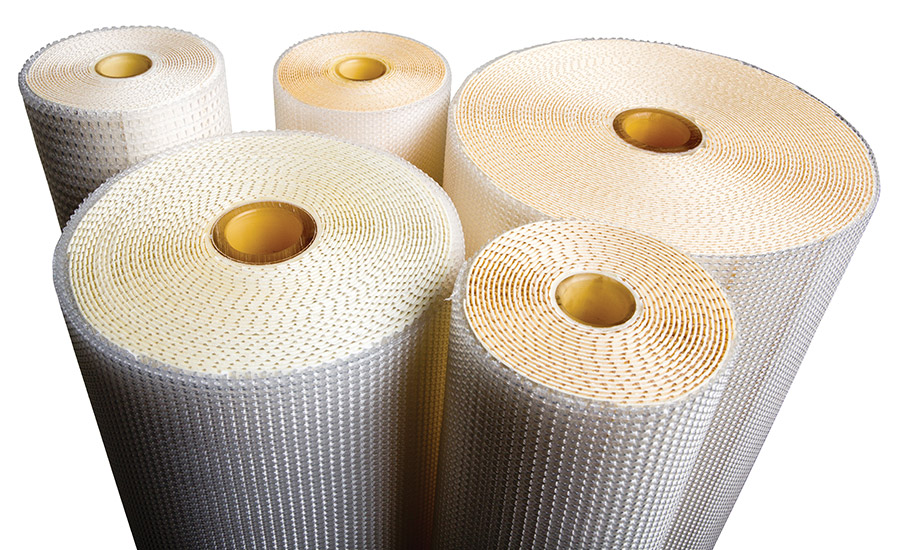

TurboClean ultrafiltration membrane elements for whey and milk processing

Following the acquisition of TriSep Corp., Microdyn-Nadir US introduced a line of ultrafiltration membrane elements. The company’s spiral-wound membranes are known for their high flux, high protein retention and long lifetimes. TurboClean hard-shell elements are known for being the strongest sanitary elements offering better productivity, longer operating life, the most effective cleaning and ease of installation, according to the company.

919-341-4221; www.microdyn-nadir.com

Cost-effective alternative to pasteurization

The Fuente II filter for microbial stabilization from Pall Corp. was created to meet the critical sterile water needs of the food and beverage industry, and to meet the strict microbiological specifications for both plant and ingredient water. With the Fuente II, dairy plants can now have instant, on-demand sterile water for product and flavor change outs, without the need to wait for pasteurization. It is fully food contact-compliant and has full material traceability for FDA and USDA FSMA requirements

516-484-3600; www.pall.com

Suite of membrane elements feature innovations in membrane chemistry

Toray Membrane USA offers microfiltration, ultrafiltration, nanofiltration and reverse osmosis membranes in sanitary designs. Dairy applications include milk and whey protein concentration, milk solids concentration, de-ashing, pre-concentation and permeate polishing. The company’s products are USDA-accepted and 3A/FDA-compliant.

952-484-9233; www.toraywater.com

High-quality separation and clarification in compact solutions

The Seital brand Series Se-St automatic standardization unit from SPX Flow employs a highly accurate Coriolis-type meter to provide the density of the cream coming out of the separator. The unit automatically controls separator output parameters such as skim back-pressure and cream concentration and features a touchscreen interface for adjustment of the fat quantity in milk and cream. The unit is available as a stand-alone module that can be connected to an existing separator or integrated in the same skid of a new separator.

800-252-5200; www.spxflow.com

Ceramic microfiltration membranes

Inopor offers a range of CMFM’s for isolation, fractionation and concentration of proteins. Products include membranes based on alumina, titania and zirconia. These CMFM’s are available in different diameters (25 or 41 millimeters), channel diameters (2 -6 millimeters) and number of channels per element (19 -163). This range enables optimum solutions for protein selectivity and process efficiency. Applications include manufacture of native micellar casein concentrate and isolate powders, milk protein concentrate powders, native whey protein concentrate and isolate powders, and milk standardization for high-efficiency manufacturing of cheese and yogurt.

949-421-9804; www.inopor.com/en

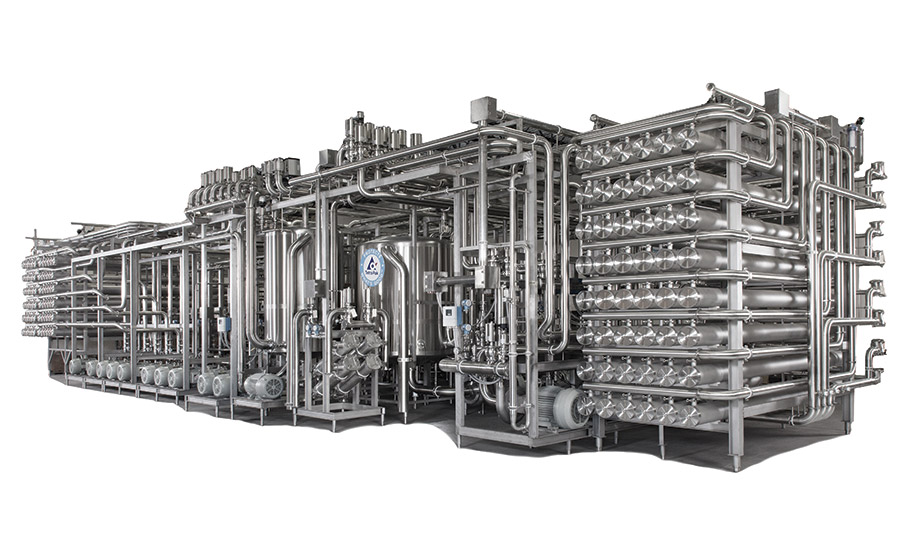

Advanced filtration and separation technologies

Tetra Pak Filtration Solutions develops natural, innovative solutions for new and highly profitable ingredients that address current and future consumer needs. Originally used primarily for water removal and protein concentration in the dairy industry, membrane filtration is now playing a crucial role as a value-adding technology in the dairy as well as other sectors of the food industry.

763-421-2721; www.tetrapakusa.com

Polymer hollow fiber modules for optimized casein/whey protein fractionation

For processors of enhanced dairy products with higher protein content and overall nutritional value, polymeric hollow fiber modules from Pentair offer a new option. They deliver comparable separation efficiency, but with reduced module costs per liter of milk processed. The hollow fiber membrane modules operate at lower temperatures compared to ceramic membranes, delivering a further cost reduction potential because the milk does not have to be heated to the temperature that ceramic membranes require.

800-218-3915; www.foodandbeverage.pentair.com

Process enables production of beneficial concentrate from skimmed milk

Alpma offers combined MF/UF plants for the production of MicCC (Micellar Casein Concentrate), a product from skimmed milk that is said to provide particular health benefits. The Alpma process comprises a combined microfiltration and ultrafiltration unit that produces MicCC through protein fractionation and subsequent concentration of skimmed and pasteurized milk – a readily available and inexpensive raw material. The resulting MicCC concentrate has a casein/whey protein ratio of up to 95/5 percent and a total protein content of more than 83%.

414-559-5961; www.alpma.com

In-line real-time NIR analytical control

ProSpect Analytical is working with whey protein concentrates and whey protein isolates, which the company says are difficult to control because of their very high concentration factor when being produced on UF or MF systems. The best way to minimize the standard deviation is to control the membrane system with in-line real time NIR analytical control, based on actual levels of protein not by volumetric concentration.

888-980-1216; www.prospectanalytical.com

Pleated filter cartridge

The PSI-Pleat filter cartridge from Powder-Solutions is more efficient and less time-consuming than traditional fabric filters, said the company. The wide-pleat spacing in a PSI-Pleat provides significantly more filtration surface area than a fabric filter, and they have greater than 99.99% air filtration efficiency, which equates to cleaner air and more time between filter replacements. And the cartridges can be installed in a matter of minutes. The PSI-Pleat is constructed of 100% polyester spun-bound media. Optional surface treatments are also available.

877-236-3539; www.powder-solutions.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!