Finding detection systems that meet all needs in a dairy processing plant

Leading suppliers talk about what’s new in detection equipment and offer tips on choosing systems that will ensure all areas of detection are covered.

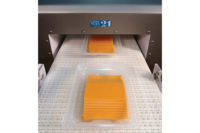

Mettler Toledo’s new Profile Advantage metal detector uses multisimultaneous frequency technology to reduce false rejects. Multisimultaneous frequency technology achieves the highest levels of detection sensitivities by analyzing product signal data captured across a wide spectrum of frequencies simultaneously. www.mt.com/pi

Thermo Fisher Scientific’s NextGuard C500 X-ray detection system features an aperture that is 35% wider and 50% taller than previous models, making it well suited to inspect larger-sized products and cases. www.thermofisher.com/nextguard

Anritsu’s XR75 Performance series features HD imaging for enhanced data analysis. In addition to hard materials like metal, it maximizes detection of soft contaminants. The system is suitable for high-speed production lines and sanitary processing environments. It also provides missing product detection, shape detection, virtual weight, count and package check. www.us.anritsu-industry.com

The new Ishida X-ray (IX) series, supplied by Heat and Control, offer manufacturers easy maintenance and stress-free operation. The range includes a robust fail-safe system that prevents a contaminated product reaching the consumer in the event of a power outage or breakdown, helping to minimize the potential for costly recalls. All models offer exceptional sensitive foreign-body contaminant detection. www.heatandcontrol.com

Teledyne Dalsa’s new BOA ID vision sensors enable faster, more accurate inspection. The sensors are available in two models. A standard IDS model includes the core 1D/2D decoders, while the expanded IDE model adds advanced direct part marking decoding, OCR and verification tools. www.teledynedalsa.com

We spoke with some leading suppliers and experts about what’s new in detection and inspection systems for dairy processing. In this article we discuss this new technology, what dairy processors are looking for and what they should be aware of.

What’s important

Just as it’s important to make sure dairy products are free from foreign bodies and contaminents, it’s important that when packaging product, lids and containers match and labels are applied correctly. We also asked suppliers how to ensure cheese (or other products) meet quality standards; and for tips on helping dairy processors conform to Food Safety Modernization Act (FSMA) regulations. Read what several experts had to say about these topics below.

Lids, containers and label inspection

“Vision systems can help meet quality standards such as verifying that a lid matches its container. They are particularly suited to prevent label mix up as well as ensure labels are not torn, flagged or applied incorrectly,” said Sarrina Crowley, marketing communications manager, Mettler Toledo, Tampa, Fla. “They can also verify that each label has the correct bar codes and nutritional information – preventing recalls and ensuring brand protection.”

Bill Makely, public relations consultant, said that Mettler Toledo makes a vision inspection system that inspects packages for correct labeling and ensures that containers and lids match. The system is able to perform high-speed label inspections on round, un-oriented products, including graphical identification, barcode reading, OCR (optical character recognition) and OCV (optical character verification), all of which identify mislabeling before a package can leave the facility.

For many manufacturers, space on production lines is limited and it can be difficult to add vision inspection equipment into the production process. Finding a vision system with a small footprint enables a dairy processor to fit the equipment into tight spaces on the production line. Thus, manufacturers can install the system where it can be most effective.

Maureen Clancy, marketing project manager for Teledyne Dalsa, Billerica, Mass., said Teledyne’s latest vision sensor combines 1D/2D code reading with OCR and verification tools to ensure all product markings are accurate, readable and traceable. The vision sensor works for a range of applications including packaging verification (reading product codes to avoid labeling mix-ups); product marking verification (validating product type, lot and expiration date codes); and product quality verification (checking markings, label position, feature presence/absence).

Meeting quality standards

“Because many dairy items have a high product effect which negatively impacts metal detector performance, most production lines will benefit by stepping up to the expanded inspection/detection capabilities offered by X-ray systems,” said Bob Ries, Thermo Fisher Scientific, Minneapolis. “Dairy production lines are also typically subjected to harsh washdown sanitation procedures. This dictates that the equipment used has to be able to handle the extreme temperature variations—going from very cold to very hot—inherent in the production and washdown.”

Ray Spurgeon, product manager, Eriez, Erie, Pa., said that, “Although metal detectors do nothing for the taste, mixing, forming or texture of dairy products, they are the ultimate final quality check that mitigate dangerous metal fragments.”

Conforming to FSMA regulations

“Metal detectors, X-ray inspection systems and vision systems all help to comply with FSMA regulations as preventative measures to ensure products are free of contaminants and labels are correct,” said Mettler’s Crowley.

Spurgeon said, “The FDA’s position is clear — processors must control metal inclusion. Metal detectors are one of the few technologies specifically mentioned as a means to attain compliance. Further, unlike the other controls (such as magnets), metal detectors identify both ferrous and nonferrous metals and can inspect the finished package.”

He continued, “Additionally, metal detectors are superior to screening equipment as screeners are limited to unpackaged, free-flowing products that often introduce metal into the product (i.e., wire).”

Kelly Sharpe, marketing manager for Fortress Technology, Toronto, noted these key FSMA objectives for dairy producers to consider:

- Sanitary design that’s easy to clean

- Equipment that is easy to maintain with parts

- Robust data collection that captures CCP performance

- Operator friendliness

Sharpe said, “It’s possible for dairy producers to stay up-to-date with FSMA requirements without having to purchase a completely new metal detector system. If [a manufacturer] currently [has] a Fortress system, it can be easily upgraded without being taken off the line, or [the company] can retrofit a detector into an existing process line.”

Thermo Scientific’s Reis said, “As food safety standards become more and more stringent, a hot topic is the detection of nonmetallic contaminants such as plastics. For example, a common request is the detection of gasket fragments. In many cases, due to the relative density of these materials, this can be very difficult. Now there are several material suppliers formulating plastics that contain dense or metallic compounds that make these materials much more detectable with metal detectors or X-ray systems.”

What’s new

We asked suppliers what new technology or features they incorporated into equipment used for dairy foods processing or packaging.

“Recognizing both the short-term and long-term needs of today’s processors and manufacturers, Anritsu’s engineers designed an inspection system with a redesigned X-ray tube and detector for significantly longer component life and improved detection levels for contaminants,” said Rob Tiernay, director of sales North America, Anritsu, Elk Grove Village, Ill. “This new technology provides excellent sensitivity at lower energy levels and a reduced cost of ownership.”

He added that the sanitary design was also improved with angled surfaces for water run-off, removable curtains for easy cleaning and a tool-less belt removal.

Eriez released a new platform for one of its metal detectors. This “cutting-edge method may improve sensitivities as much as 300% over traditional boundary detection for challenging dairy applications,” said Spurgeon. The new platform “enables the metal detector to look at a 3-D representation of product signals. From this 3-D model, it utilizes key features about the product that are not visible using standard boundary techniques.”

He added that it’s now possible for food processors to detect metal contaminants in small sizes that were previously only attainable using X-ray. “This helps processors comply with increasingly stringent requirements by their customers and regulators,” said Spurgeon.

Mettler Toledo featured a new metal detector at Pack Expo in November. Makely said that the system “uses multiple frequencies to detect contaminants in high moisture and high salt products (such as cheeses) without producing false rejects due to product effect, as happens with traditional metal detectors. This enables the system to detect metal contaminants accurately without wasting product due to false readings.”

Rick Cash from Thermo Fisher Scientific said that companies are asking to include more sanitary design elements into products, notably checkweighers and X-ray systems.

“We believe as more companies focus on the food safety of their packaging processes, sanitary design will become a more requested element,” said Cash.

What’s in demand

At the Pack Expo Show in November, we asked several exhibitors what is on the minds of dairy processors regarding detection/inspection systems and what are these processors looking for.

“Customers frequently request improved detection on metal through metalized packaging, and X-ray is the solution for those types of applications,” said Tiernay. “Dairy is typically tough on equipment and a frequent concern is the washdown rating that our inspection equipment provides. New sanitary improvements in design were frequently discussed with dairy processors.”

Spurgeon said that dairy processors are asking how they can improve metal detector sensitivities to detect even smaller metal contaminants in their always-challenging conductive products. Other dairy processors are asking about the equipment’s ability to handle high-pressure washdown.

Cash said manufacturers are interested in communications analytics for quality and production assessment. Concerns about proper marking and identification were highlighted. He added, “We expect to see more requests for label/package identification in the near future.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!