Investments in UHT processing equipment helps Agropur grow

Investments in ultra-high temperature processing equipment help Agropur USA gain business in the burgeoning market for extended-shelf-life products.

Extended-shelf-life beverages are conveyed from the filling room to the packaging room where they are collated into cases. Photos by Nate Larson

Agropur produces its Natrel brand of Dynamoo flavored milks in St. Paul, Minn. The plant also manufactures aseptically processed and packaged milks for other companies.

A filling machine forms packaging from a roll of film at the Agropur plant in St. Paul, Minn.

A roll of film will be fed into the filling machine (previous) and formed into packages. Promoters of aseptic packaging note that shipping a roll of film rather than a truckload of bulky empty containers lowers a dairy’s carbon footprint.

Agropur processes fresh milk and packages it in plastic gallon jugs and smaller plastic and paper formats.

A gantry in the receiving area has improved safety. Previously, workers wore safety harnesses when they wanted to gain access to the top of tankers.

Agropur has three ultra-high temperature processing systems used to pasteuirze dairy and nondairy beverages. The dairy added a third filler in the spring to meet the growing demand for aseptic products.

Jim Schultz is the vice president of operations for Agropur’s Natrel USA division. He oversees the production of the fresh dairy products extended-shelf-life milk and nondairy beverages.

he future is bright for the aseptic packaging of dairy and processed foods in North America. That’s the conclusion of a 2012 study by the research firm Markets and Markets. Among the reasons the Dallas-based firm cites for optimism are: increasing demand for packaged food, changes in the food manufacturing industry, more emphasis on product safety and changing food habits. Milk accounts for the major market share (42%) of aseptically packed products followed by other beverages (38%); the rest is made up by other dairy products.

These trends would not surprise one U.S. milk processor. Agropur, St. Paul, Minn., is thriving in contract manufacturing aseptic and extended-shelf-life (ESL) dairy and nondairy beverages. About half of the plant’s production is in long-shelf-life products. The dairy also processes HT/ST (high temperature/short time) milk in formats ranging from paper half-pints to plastic gallons.

Agropur’s Natrel USA division is a subsidiary of Canada’s second-largest dairy processor and the seventh largest in North America, according to the Dairy 100, Dairy Foods’ annual list of dairy processors. The Minnesota-based division includes another aseptic plant in Grand Rapids, Mich. The Canadian parent also owns a cheese and ingredient division in the United States, which is operated separately from the fluid milk operation. (See related article on page 59.)

The worldwide demand for ESL products is large and the dairy is investing to serve this market for its own brand and for contract manufacturing customers. ESL products are attractive because they deliver higher margins compared to fresh milk products. Producing them, however, requires a bigger infrastructure, noted Eric Brunelle, the division’s president.

In 2008, Agropur bought Schroeder Milk, a long-time independent dairy processor. The plant is located on acreage that used to be the Schroeder family’s dairy farm. The company is now known as Agropur. Natrel is the brand name for Agropur’s aseptic products. A Natrel sub-brand is Dynamoo, a line of flavored milks. The plant still processes fresh milk and cream (with the HT/ST pasteurization process) under the Schroeder name and for co-manufacturing clients.

In 2009, Agropur purchased the Farmland Dairies plant in Grand Rapids. This facility produces aseptic lactose-free milk beverages, fitness drinks, soups and broths. Agropur is investing in new equipment at both plants.

VP of Operations Jim Schultz took Dairy Foodson a tour of the St. Paul facility. In the receiving area, tankers hauling conventional or organic milk arrive throughout the morning and afternoon from U.S. dairy farmers. Though owned by a Canadian dairy cooperative, milk from across the border cannot be brought to the United States. Instead, milk is sourced from Minnesota and surrounding states. Some organic milk arrives from as far away as Texas.

The plant can receive two milk tankers at a time. One of its good manufacturing practices is the use of color-coded hoses to empty the tankers: red for dairy milk and green for soy products. An on-site lab tests samples from each load for antibiotics, somatic cell count, direct micro count and temperature, as well as organoleptic attributes. An off-site lab runs other tests.

To improve worker safety, the plant built a gantry over the receiving area. Receivers climb a stairway to access the top of the tanker. The platform also allows safer access to the porthole to draw samples. Before Natrel built the gantry, receivers had put on a safety harness (which they found awkward to wear) to access the top of the tanker.

The processing room holds two HT/ST systems. One is used to pasteurize milk and nutritional shake products; the other is used for byproducts, Schulz explained. The Schroeder brand cream, known for its purple carton, is vat-pasteurized. After separation, the milk is pumped to one of four 1,000-gallon pasteurized tanks. Three of the tanks are used for milk; the fourth is used for buttermilk.

Ingredients for flavored milk and other protein-enhanced dairy beverages are prepped in a room separate from the processing area. Dry ingredients (such as cocoa powder or whey protein) or liquid fats are poured by hand into a bin and liquefied. An eductor in the bin sucks the dry powders into the liquid medium and thoroughly blends the two. The blended product is held in one of two 12,000-gallon blend tanks.

From the processing room, the pasteurized milk flows to the filling room. Agropur has five fillers handling half-pint to gallon formats and one bag filler (packaging milk for foodservice accounts). Schroeder brand milk and nutritional shakes for a contract manufacturing client are filled on these lines.

The smaller-format fillers can produce 1,000 cartons (like half-pints for school milk) per minute. After filling, the containers are code-dated and conveyed to the packing room. Depending upon the customer, the products are collated and packaged in corrugate cases or in plastic crates.

There is also an 18-valve filler for quarts and half-gallons and a 26-valve filler for gallons. Plastic gallons arrive from a blow-mold vendor and are de-bagged in a separate room. The plastic containers are filled, caps are applied and then the package is code-dated. The filled bottles are conveyed automatically to the case stacker room and then to the refrigerated warehouse. Depending upon the customer, the packages are put into milk crates, corrugated boxes, bossey carts or caseless pallets.

Automation has helped efficiencies and improved worker safety. Robotic palletizers build pallets. One unit can build three different pallets in three different configurations at the same time. These are shrink-wrapped and sent stored on racks until ready to be sent to a customer. The company’s ERP system keeps track of everything.

UHT processing

Schultz then took Dairy Foods to the aseptic processing plant. Agropur has three ultra-high temperature processing systems that pasteurize dairy and nondairy beverages for aseptic or extended shelf life packaging. The UHT systems use steam injection or indirect heating. The steam-injection processors, for example, pasteurize milk for two seconds at 280 F under pressure. This process is considered to be gentler for white milk products. The indirect heating aseptic processor is used primarily for chocolate-flavored products.

To meet current demand for aseptic processing (and to take on additional business), Agropur is installing a third aseptic filler this spring. The aseptic filler forms the beverage packages from a single roll of recyclable stock. The material is fed into the filler and goes through a peroxide bath that sterilizes the medium. Then it is formed into a tube shape, filled with milk and the top and bottom of the carton are cut and sealed. The Natrel Dynamoo flavored milks are produced here, along with beverages for contract manufacturing clients.

The filled containers are conveyed to the packing room. Samples from each run are held in an incubator room warmed to 95 F. When they pass the test, the lot is released.

After processing, the ESL beverages (organic milk, for example), are filled in gable-top paper cartons on two half-gallon filling machines. The ESL packages are conveyed into the same packing room as the aseptic cartons. Two robotic palletizers are at work building pallets. One robot can build three pallets at one time; the other can build two. The pallets are wrapped in plastic and stored in a refrigerated warehouse until they are trucked to customers.

The dairy has built a strong co-packing business in ESL and aseptic products by being a good processor and being responsive to customers. In 2013, the sales in this Agropur division increased 6% because of several new manufacturing agreements, according to the company’s annual report. Brands come to the dairy because of its reputation for quality manufacturing, said VP of Finance David Ellis. Through automation and information systems, the company has also become more efficient as a manufacturer.

“We understand this segment of manufacturing and have long-term relationships with our customers. The company will continue to grow by proactively addressing customer needs, maintaining strong business partnerships and investing in our plants to expand manufacturing capabilities,” Ellis said.

Making value-added beverages will be the growth engine for the company, said Director of Marketing Eric Jacobson. The longer shelf life of ESL and aseptic milks also means that a processor can ship the products further from the plant. ESL and aseptic products also are attractive because they deliver higher margins compared to fresh milk products. Producing them, however, requires a bigger infrastructure, Brunelle noted.

Brunelle is realistic about the fluid milk industry in the United States, pointing out the steady annual decline of sales of fresh milk. Export markets, on the other hand, are robust. Asia (particularly China), represent a huge potential market for UHT milk.

Worldwide demand for milk exports

According to the U.S. Dairy Export Council, exports of fluid milk and cream to the Far East rose 224% from 2012 to 2013. Although USDEC’s statistics do not note the processing technique, presumably, because of the distance traveled, some of these products are aseptically packaged. Of the 86.9 million liters of milk and cream exported in 2013, U.S. processors shipped 12.7 million liters China, Taiwan, South Korea, Japan, Southeast Asia and Singapore. After Canada and Mexico, these countries represent the second largest export market for fluid milk and cream, according to USDEC.

While Agropur also processes plant-based beverages, management is committed to milk, as one would expect from a cooperative owned by dairy farmers. “Milk is the foundation of our company, so we won’t be abandoning dairy,” Jacobson said.

At-A-Glance

Natrel Division USA, St. Paul, Minn.

Interstate Milk Shippers plant 27-421 (97% enforcement rating, January 2014)

Size: 154,000 square feet on 23 acres

Products made: rBST-free white and flavored milk, heavy whipping cream, half ’n half, buttermilk, organic milk, nutritional drinks and shakes and sport drinks. Nondairy beverages (soy, rice, coconut, and almond) coffee creamers, broth and sauces.

Accreditations: Oregon Tilth Certified Organic, Blue Ribbon Kosher, Orthodox Union Kosher, SQF 2000 Level 3 Certified

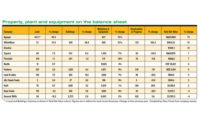

Pasteurizers: Two high-temperature/short-time, one vat pasteurizers (cream) and three ultra-high temperature (steam injection and indirect heating)

Aseptic and ESL Fillers: three 250-milliliter/8-ounce Prisma aseptic; two 64-ounce ESL; one quart ESL

HT/ST fillers: three half-pint; one quart; one paper half-gallon; one half-gallon jug; one gallon jug; one bag-in-box 5-gallon

Storage: Four 10,000-gallon aseptic tanks, one 3,000-gallon aseptic tank; two 20,000-gallon pasteurized tanks; two 8,000-gallon pasteurized tanks; 10 raw milk tanks with a total capacity of 440,000 gallons; four cream tanks with a total capacity of 28,000 gallons; bulk corn oil, fructose, corn syrup silos.

Refrigerated warehouse: 25,000 square feet, 2,200 pallet positions, 10 truck bays.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!