Tetra Pak: Equipment for Cheesemaking

|

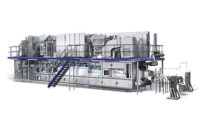

Tetra Pak recently launched the next generation of its cheddar cheese blockforming unit. The new Tetra Tebel Blockformer enables cheese processors to improve environmental performance, reduce costs and minimize product loss. The new units offer a 25% CO2 reduction compared to the company’s Blockformer 5 TwinVac version. The reduced use of air, water and electricity results in a 20% running cost reduction per kilogram of cheese. Among the new features are: a door system that reduces product loss; integrated curd-air separation for easy cleaning; vacuum pumps with frequency controllers to save energy; a tower design that reduces wear and increases quality; a guillotine system that cuts downtime; an elevator cylinder for easy, accurate operation; and a user-friendly control system.

Tetra Pak

320-485-4401

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!