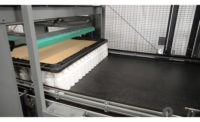

Capable of handling the entire dosing and packaging process while meeting food and pharmaceutical industry standards, the RNx platform ensures product quality through gentle handling. With its dosing module, it offers the option of using auger fillers for difficult-flowing powders and granulates, or a tipping filler for free-flowing goods. In the sealing module, extended sealing times create tight and reliable pouch seals. Grippers accurately position the sealed pouches into a transport module.

An integrated weight control system (WCS) ensures 100 percent inline weight control. Faulty products are automatically ejected via a dump gate to guarantee high product quality, while good products are passed through an equalizer unit and stacked according to the requested count. The stacked products are transferred to the side loading cartoning unit, which is capable of handling single or double stacks of sachets intermittently at an output of up to 100 cartons per minute. The format-flexible cartoner can support the use of a variety of cartons, whether for attractive point-of-sale presentation or tight-fitting racks or drawers.

The RNx platform can be customized to handle various pouch sizes and can include optional modules such as leaflet insertion, carton coding, carton rejection and an after-cartoning checkweigher. In addition, the system is easy and efficient to operate via touch screen, and provides clear and visible depiction of product flow and processes.

“There is increasing demand in the North American market for products such as drink sweeteners and pain relievers to be packaged in flat pouches. Our packaging and cartoning system gives manufacturers the ability to produce these pouches with high efficiency, cost effectiveness and high hygiene standards.” said Frank Buehler, product manager, Bosch Packaging Technology.

Bosch Packaging Technology

www.boschpackaging.com