Tetra Pak launches Tebel Casomatic SC 7 for cheese

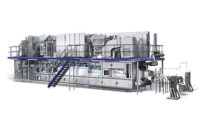

Tetra Pak has launched a new version of Tetra Tebel Casomatic that enables cheese producers to achieve superior and more consistent product quality without compromising food safety, while reducing operating costs and minimizing their environmental impact.

Tetra Pak has launched a new version of Tetra Tebel Casomatic that enables cheese producers to achieve superior and more consistent product quality without compromising food safety, while reducing operating costs and minimizing their environmental impact.

“The introduction of the Tetra Tebel Casomatic SC 7 module reinforces Tetra Pak’s commitment to innovation and design, consistently improving our equipment and solutions in order to enable our customers to get the quality of cheese and whey and the resulting profits they demand,” said Tetra Pak Tebel Managing Director Charles Todd. “Tetra Tebel Casomatic SC 7 is the new way to first-rate production of first-choice cheese.”

Tetra Tebel Casomatic SC 7 helps processors in the semi-hard cheese segment make superior quality whey and cheese with better accuracy when it comes to product properties like moisture content and weight. To further secure product quality Tetra Tebel Casomatic SC 7 comes with pre-defined and validated performance guarantees on hygienic conditions.

Tetra Tebel Casomatic SC 7 is self adjusting for optimal performance during its whole life cycle. Uptime can be increased due to improved hygienic condition of the production. This enables customers to produce cheese and whey more efficiently than ever before.

With Tetra Tebel Casomatic SC 7 fresh water consumption during production and product waste after a full production cycle can be reduced compared to the previous generation. This means large savings reduced cleaning and waste-disposal costs and less impact on the environment.

“We believe that the way forward is to continuously improve our core cheese making equipment while expanding both our full line and whey processing solutions,” said Trevor Clarke, vice president of Tetra Pak Cheese and Powder Systems. “We recognize that customers require solutions, not just components, so we build efficiency, productivity and sustainability into all of our processing steps, enabling manufacturers all over the world to get the most out of their plant.”

Tetra Tebel Casomatic SC 7 is setting new performance standards for production of semi-hard cheese. -

--Downtime cut by more than 40 percent – CIP-downtime is reduced to only 1.5 hours for a four-column unit, allowing longer production runs. Due to its new machine design, CIP cycles are shorter and less energy and chemicals are wasted.-

--Increased hygienic conditions of whey: Tetra Pak can now guarantee coliform counts below 10 cfu/gram and high thermo-resistant bacteria counts below 1000 cfu/ml even after 22.5 hours of continuous production, ensuring whey quality suitable for high-end whey processing applications.-

--30% improvement in weight accuracy.-

--Reduced product waste by around 95%.-

--Decreasing water consumption by around 65%

Tetra Tebel Casomatic SC 7 enables customers to reduce the consumption of fresh water in production by around 65 percent and the total water consumption – during both production and CIP – will be around 60 percent less.

Tetra Pak Processing Systems

www.tetrapak.com

Tetra Pak has launched a new version of Tetra Tebel Casomatic that enables cheese producers to achieve superior and more consistent product quality without compromising food safety, while reducing operating costs and minimizing their environmental impact.

“The introduction of the Tetra Tebel Casomatic SC 7 module reinforces Tetra Pak’s commitment to innovation and design, consistently improving our equipment and solutions in order to enable our customers to get the quality of cheese and whey and the resulting profits they demand,” said Tetra Pak Tebel Managing Director Charles Todd. “Tetra Tebel Casomatic SC 7 is the new way to first-rate production of first-choice cheese.”

Tetra Tebel Casomatic SC 7 helps processors in the semi-hard cheese segment make superior quality whey and cheese with better accuracy when it comes to product properties like moisture content and weight. To further secure product quality Tetra Tebel Casomatic SC 7 comes with pre-defined and validated performance guarantees on hygienic conditions.

Tetra Tebel Casomatic SC 7 is self adjusting for optimal performance during its whole life cycle. Uptime can be increased due to improved hygienic condition of the production. This enables customers to produce cheese and whey more efficiently than ever before.

With Tetra Tebel Casomatic SC 7 fresh water consumption during production and product waste after a full production cycle can be reduced compared to the previous generation. This means large savings reduced cleaning and waste-disposal costs and less impact on the environment.

“We believe that the way forward is to continuously improve our core cheese making equipment while expanding both our full line and whey processing solutions,” said Trevor Clarke, vice president of Tetra Pak Cheese and Powder Systems. “We recognize that customers require solutions, not just components, so we build efficiency, productivity and sustainability into all of our processing steps, enabling manufacturers all over the world to get the most out of their plant.”

Tetra Tebel Casomatic SC 7 is setting new performance standards for production of semi-hard cheese. -

--Downtime cut by more than 40 percent – CIP-downtime is reduced to only 1.5 hours for a four-column unit, allowing longer production runs. Due to its new machine design, CIP cycles are shorter and less energy and chemicals are wasted.-

--Increased hygienic conditions of whey: Tetra Pak can now guarantee coliform counts below 10 cfu/gram and high thermo-resistant bacteria counts below 1000 cfu/ml even after 22.5 hours of continuous production, ensuring whey quality suitable for high-end whey processing applications.-

--30% improvement in weight accuracy.-

--Reduced product waste by around 95%.-

--Decreasing water consumption by around 65%

Tetra Tebel Casomatic SC 7 enables customers to reduce the consumption of fresh water in production by around 65 percent and the total water consumption – during both production and CIP – will be around 60 percent less.

Tetra Pak Processing Systems

www.tetrapak.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!