So You Need to Buy a Pump

Applying Total Cost of Ownership

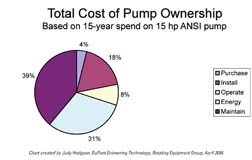

Total cost of ownership is an evaluation tool that looks at a piece of equipment and the total operating costs associated with using that equipment for the duration of its lifespan. The total cost of ownership includes not only the purchase price but also the energy used, maintenance and operational costs. Over its lifetime these additional costs can make the initial purchase price insignificant. Applying this sort of evaluation is already common in many industries and is just emerging in dairy operations.It is particularly useful for pumps where the cost of their energy consumption is so significant. The view of a pump purchase can change dramatically when considering the total cost of ownership. The accompanying illustration (see page 56) shows lifetime pump costs for a typical industrial pump. Using this tool as part of the purchasing decision can generally yield long-term improvements in plant profitability.

The initial reaction when hearing about such a concept is, "That's very nice but I don't have time for that sort of research. I've got a plant to run." With that in mind let's take a look at some of the total cost factors and how to get a handle on them. This approach is illustrated on the accompanying spreadsheet.

Purchase Price and Installation

This is easy. You've got bids from one or more trustworthy vendors. This is the basic starting point and the point beyond which many people never move. Unfortunately the purchase price can easily be as little as 4% of the total cost of owning and operating a pump. The price difference between vendors quickly becomes insignificant when put in this light.

How much will it cost to change the pump? If a newer model or different vendor is being considered piping or mounting changes may be required. A quick estimate of those costs can be made and added to the purchase price.

Lifetime and Energy Cost

Pumps tend to have fairly long working lives in dairy operations. Your actual experience will vary depending upon the hours of running time, severity of the duty and effectiveness of maintenance. You, or other members of your team, probably have a useful sense of the lifetime for a pump in your facility. Our experience is that few pumps are used less than seven years and many are still running at ten.It's more important at this stage to select a realistic number than to spend hours doing a study. The number will be used for comparative purposes only with one important exception. If your evaluation strongly suggests that one vendor will provide significantly longer life, this should be considered since it will lower the total cost of ownership over that extended lifetime.

Energy consumption is over 30% of the total cost of ownership for an industrial pump. This value is probably even higher given the preponderance of centrifugals used in most dairy operations. Given the recent rise in energy costs this factor is likely to become even more important in the years during which any new pump is operating.

The good news is that it's relatively easy to compare efficiency. Obtaining the brake horsepower (actual horsepower used) and the motor size allows you to calculate power usage. Factoring this by the estimated hours of operation and the power costs quickly provides a useful number. As can be seen in the accompanying example which is modeled on a centrifugal, power consumption costs dwarf the original price of the pump.

Maintenance

Typically pump maintenance is the single largest non-energy cost over the lifetime of the pump. Unfortunately it is also one of the most difficult areas to quantify. A starting point is the price of replacement components. These fall into two categories. Seal kits and elastomers will need to be replaced several times during the pump's lifetime. Other major components, such as motors, shafts, rotors and impellers, may not need replacement for years. Obtaining these prices is generally as simple as a phone call to the vendor.Installing these parts requires maintenance time. To factor that in obtain an estimate of the time required to replace the above components and multiply that by your hourly maintenance costs. This will be your costs for replacement of each of the typical repair components.

Determining the frequency for these replacements depends on experience and an evaluation of the technology. Within your organization you probably have that experience for existing products. A discussion with maintenance or operations people will often be quite revealing since different pumps require surprisingly different amounts of service. The folks who deal with them almost always have strong opinions on these subjects and can provide useful guidance if not always hard numbers.

Our own experience is that seals and elastomers typically last from as little as 4 months to three years depending upon the pump and the application. Motors, shafts and impellers are generally replaced once or twice during the life of a centrifugal pump. Positive pumps often require rotor replacement on a 3-4 year average with motor and shaft life similar to centrifugals.

In considering a new vendor or improved technology judgment must be used. New and better ways of doing things have dramatically reduced pump maintenance over the years. Determining the impact of a proposed improvement requires careful questioning and, at the end, the best application of your experience and judgment. This remains an important area for potential improvement since there are numerous cases where seal replacement went from a few months to two years when a new vendor and improved technology was applied.

Having come up with your best estimates of the service intervals you can now apply them to the pumps under consideration using the costs of the parts and labor that will be required to repair the pumps during their lifetime.

Operations

In a typical industrial environment the cost of operating a pump consists of setting up the necessary controls and the operator time involved in running the pump. These factors apply in dairy but are often negligible compared to other operational issues that can add to the total cost of ownership. Three of these that are often worth consideration are:Cleaning in Place

Many positive displacement pumps are still partially disassembled and hand-cleaned. This not only requires a daily commitment of operator time but also produces considerable damage to the carefully machined rotors. This increases maintenance costs. Newer, CIP'able pumps generally require a larger installation investment but eliminate the daily commitment of operator cleaning time and dramatically reduce maintenance costs.

Product Quality

More efficient pumps handle products more gently and produce less damage to butterfat. In many operations this is an important issue, especially considering the cost of cream.

Installation of CIP'able pumps and the use of highly cleanable designs can contribute to longer shelf life and lower counts.

Operational Efficiencies

Specific pumps can provide benefits such as reduced air entrainment, superior handling of solids, better evacuation of tanks and faster CIP cycles. The operational advantages of each of these can often pay for their higher initial cost in an attractively short time.

You may chose to add one or more of these as contributors to the cost of selecting a specific pump.

The Evaluation

With the above information in hand it's relatively easy to assign dollar amounts and add the numbers that will show the total cost of owning a given pump. Factoring in the energy, maintenance and operational costs can provide a valuable decision-making guideline. The results are often very different from the more typical approach of checking the bottom line of several quotes. In the accompanying example energy costs were a major factor. The small reduction of 10 minutes of CIP time yields surprising results over the lifetime of the pump.

Evaluating the total cost of ownership requires a little more research and conversations with maintenance and operations. Committing the extra time to the process not only should yield better long-term decisions but a better understanding of how pumps, or other equipment, affect maintenance, energy consumption and operations. In the case of pumps, an analysis of competitive equipment, and a purchase based on the lowest TCO will almost certainly result in reduced operational, maintenance and energy costs.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!