Formulating Aerated Dairy Foods

Indeed, aerated dairy products have entered the U.S. marketplace and consumers have been very receptive. Because the production of refrigerated whipped products is somewhat deli-cate, manufacturers must understand how formula and process impact stabilization, which in turn influences the finished product's characteristics. Recognizing the growth opportunity in this cate-gory, and the need for processor education, G. C. Hahn & Co. USA, Erie, Ill., held a seminar at the Center for Dairy Research at the University of Wisconsin-Madison this past May. Here is a brief overview of the technology presented.

The act of stabilization

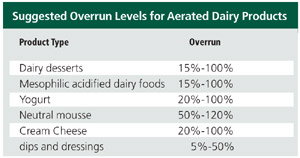

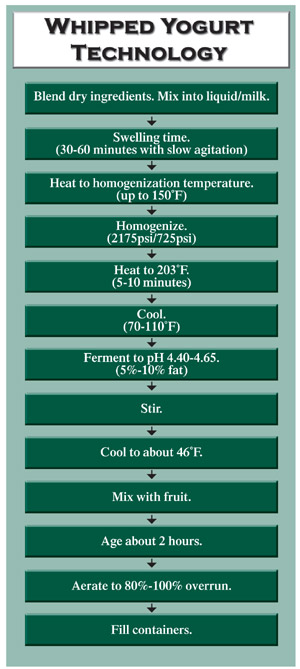

Many dairy foods can be aerated; however, the two primary classes of dairy products that are being aerated are those with low pH (fermentation with mesophilic or thermophilic cultures) and neutral products such as cream topping. When increasing the volume of a product through aera-tion, the characteristics of the product can be adjusted according to the desired specification. Two of the characteristics most influenced by ingredients and process are mouthfeel and texture, and both can be managed by choosing the right stabilizer system.Choosing the right stabilizer system is as important to the aerated product's success as is raw material and ingredient quality. In fact, the stabilizer system directly impacts finished product quality and shelf stability. These two factors gain additional significance when long transporta-tion distances and, more so, varying altitudes, enter the picture. Both of these can have a negative effect on product quality if the product is not properly stabilized.

Every stabilizer system should include an emulsifier from the group classified as mono-diglycerides. Experience shows that one of the most effective emulsifiers is lactylated mono-diglyceride. Other components of the stabilizer system may include starch, gelatin, carrageenan, guar, xanthan gum and locust bean gum.

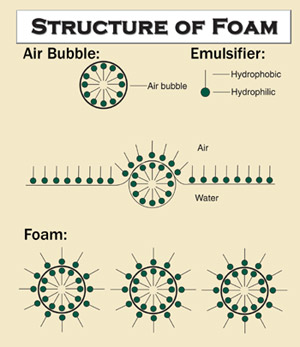

During product cooling and aging, fat particles crystallize with the emulsifiers crystalliz-ing in the fat. Crystals drift onto the fat's surface promoting coalescence of the small fat spheres. This causes viscosity to increase and proteins to hydrate. Basically, a web is built for better ab-sorption and support of gas.

During the act of aeration, the aqueous phase (dispersing agent) and the hydrocolloids dis-solved in this phase are united by gas at high turbulences. Emulsifiers reduce the interfacial ten-sion. The hydrophilic-lipophilic balance is very important. The mixing head mechanically crushes large gas bubbles into very small bubbles. Stability of the foam is also achieved through the pres-ence and/or addition of fat and milk protein. The increase of viscosity and the gel network formed by the stabilizers and emulsifiers guarantees homogeneous gas bubble distribution at low whip-ping temperature, which also results in fat crystallization. As you can see, each individual proc-essing step impacts the functionality of the added hydrocolloids and emulsifiers, which is why it is so critical that a stabilizer system be custom designed for your company's product and process.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!