Articles by James Carper

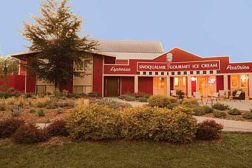

‘We make perfect ice cream,’ says the owner of Snoqualmie Ice Cream in Washington state. Organic milk and cream, innovative flavor combinations and homegrown herbs and fruits contribute to the products’ popularity.

Read More

Three Twins Ice Cream aims for the top

Neal Gottlieb is taking aim at the top national brands of super-premium ice creams. He calls his organic products ‘inconceivably delicious.

March 9, 2013

Innovations

New dairy products are re-shaping grocers' dairy aisles

New dairy products from Kraft and Land O'Lakes are more like ingredients than actual foods. So where do they belong?

February 28, 2013

Free-standing inserts

Muller Quaker features its new yogurts in this week's FSIs

The dairy partnership sells conventional and Greek yogurts.

February 20, 2013

Rhino Foods is rolling in cookie dough

Rhino Foods measures everything it does. Employees work to a goal and are rewarded when they meet the targets. Management’s reward is a smooth-running organization that fulfills customers’ needs.

February 15, 2013

Rhino Foods: Ice cream's trendsetter

Rhino Foods made a name for itself by developing cookie dough for Ben & Jerry’s. But that’s just part of what makes this Vermont dairy processor and baker noteworthy. The forward-thinking company is a trendsetter in employee relations, too.

February 14, 2013

New uses for familiar dairy products, cheese and butter

Processors create new usage occasions for cheese and butter.

February 12, 2013

Free-standing inserts

Party planning and a little 'monkey' business from Kraft in this week's FSIs

Dairy marketers gear up for the Super Bowl and promote a clean label in this week's free-standing inserts.

January 23, 2013

A look inside HP Hood's Sacramento plant

HP Hood fills 600 bottles a minute on its new aseptic line in its Sacramento, Calif., plant. The company processes dairy and nondairy beverages in aseptic and extended shelf life packages.

January 18, 2013

While many processors specialize, HP Hood does it all

While many processors specialize, HP Hood does it all: milk, ice cream, cheese, yogurt, other cultured foods and nondairy beverages.

January 15, 2013

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing