Case Studies

Hershey Creamery Co. employs Savanna.NET WES to improve reliability and efficiency.

Read More

X-ray specs

Belgian dairy producer Olympia uses X-ray systems for QC

One machine can assess 10,000 small packages of yogurt an hour. A second machine for larger yogurt containers reaches speeds of 4,000 cups per hour.

September 4, 2017

Data. Ta-da!

How Michael Foods benefits from Quality Intelligence software

With QI software, production lines now run within tenths of a gram of target for weight control. The company paid for the enhanced SPC project through gains in productivity.

April 28, 2017

Please sleeve

Sleeve packaging is the right solution for a Finnish yogurt maker

Juustoportti can output 200 4-packs products a minute thanks to a robotic solution by equipment maker Gerhard Schubert.

March 20, 2017

Why it’s ERP

ERP system ensures that a dairy processor complies with FSMA

A critical element of converting from handwritten notes to the ERP system was detailed process mapping.

December 20, 2016

Curds and weigh

Cheese company upgrades to flexible weighing and labeling equipment

Packaging as many as 20 different cheese items and sizes each day, Laubscher needed equipment that would upgrade its processes and improve its record keeping.

September 26, 2016

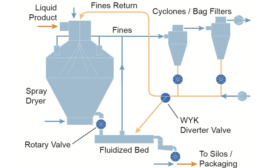

Baby powders

Sanitary valves aid in hygienic processing of powdered products for infants

Germany’s Töpfer requires the highest hygienic standards for their powder rotary valves and diverter valves.

September 22, 2016

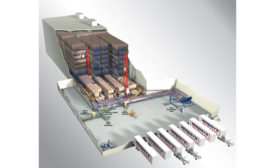

Powder production

Bulk handling system improves efficiency, sanitation and quality for dairy processor of dry milk solids

To comply with government requirements and customer demands, Franklin Farms East installed a bulk bag discharging system from Flexicon Corp.

September 22, 2016

Move on

Consider an eccentric disc pump for ice cream processing lines

With supply tanks 220 meters (720 feet) from the ice cream freezers, a Belgian ice cream processor found that powerful eccentric disc pumps solved a problem.

August 4, 2016

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing