Food Safety for Dairy Processors

Food safety

WhiteWave recalls half-gallon containers of soymilk

Plant workers mixed up the carton packaging, the company stated. The recall is not because of contamination during the manufacturing process.

May 19, 2014

Equipment design can reduce the risks of food-borne illness

Hard-to-clean dairy processing equipment is poorly designed equipment. Hard-to-reach areas and nooks and crannies probably will not be properly cleaned and sanitized.

May 13, 2014

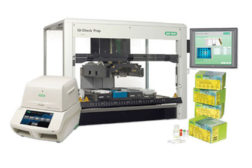

Equipment, lab tests, employee training contribute to food safety

Go beyond HACCP plans and GMPs to assure that dairy foods are manufactured safely. Take advantage of advances in CIP technology, detection devices and environmental air samplers.

April 6, 2014

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing