Anuga FoodTec 2012 saw more visitors, international participation, exhibitors

The recently concluded Anuga FoodTec 2012, held in Cologne (Koeln), Germany, posted its best event result to date. Anuga FoodTec’s visitor numbers grew by around 25%, totaling more than 42,000 trade visitors from 131 countries.

The proportion of visitors from abroad increased by 16% to 58%. The numbers of visitors from eastern Europe — especially from Russia, Ukraine, the Czech Republic and Poland — and from Turkey, increased in particular. Considerably more specialist buyers from Asia — in particular from China, Japan, Thailand and India — also visited Anuga FoodTec.

Exhibitor participation in Anuga FoodTec also grew by more than 10%. 1,334 suppliers from 41 countries presented their technical innovations and solutions in Cologne. At the same time, foreign participation increased by 5% to more than 50%.

The next Anuga FoodTec will be held from 24th to 27th March 2015.

www.anugafoodtec.com

On the following pages is a look at some of the equipment for dairy foods processing introduced at the show.

Exhibitor: Koch Membrane Systems

Product: SR3D nanofiltration (NF) element

The SR3D membrane is the next generation in a wide range of cost-effective solutions to help food and beverage companies increase efficiency and streamline processes. This unique spiral membrane is ideal for a variety of sanitary applications in the dairy, food and beverage, industrial biotechnology and pharmaceutical intermediates markets, including whey de-mineralizing, lactose, sugar and enzyme concentration, alcohol reduction, purification of organics, and clarification of pharmaceuticals.

“The new SR3D offers several advantages,” said Martin Awe, European Business Manager for Industrial and Life Sciences. “This membrane was specially designed for stable flux rates over longer periods of time and provides up to 20% higher flux than other commercially available membranes. Combined with higher deashing capabilities it allows companies to reduce operating costs and increase yield.”

In addition to the SR3D membrane, KMS offers a complete line of spiral, tubular and hollow fiber sanitary membranes for concentration, clarification and purification of food and food ingredients, including protein recovery, sweetener and dextrose clarification, juice clarification, citrus debittering, vinegar clarification, and starch and enzyme processing.

KMS also provides a full range of membranes to maximize water use and close the process loop in food manufacturing operations—not only removing contaminants, recovering materials, and purifying process streams within the plant, but also treating the outgoing effluent to meet environmental discharge standards.

Exhibitor: GEA Procomac

Product: Aseptic Dual Filling System

GEA Procomac exhibited its new aseptic dual filling system for the filling of PET bottles with products containing particulates. The new system is composed of two separate filling carousels: the new aseptic piston doser PX for solid particles with set volume from 30 to 150 ml and the volumetric electronic filler Fillstar FX, an industry standard for aseptic beverages filling. Filling of the bottles takes place in two operations: first the dosing of the solid particles; then the addition of the liquid phase. The dual fill system requires a two-stream process line: one dedicated to the thermal treatment of the pieces and the other to the thermal treatment of the clear liquid.

The new Aseptic Dual Filling System is designed for the bottling of still beverages, both High Acid and Low Acid, containing pulps, fibres, and pieces of fruit or cereals with dimensions up to 10x10x10 mm, or products whose density does not allow the consistent distribution of the pieces.

Exhibitor: Blendhub

Product: Blendhub Powder Blending solution

Powders and powder blending are used in nearly all industry segments. In the Food and Food ingredients industry powder blends are either produced in-house, contract manufactured externally or supplied as a formulation by specialized suppliers.

The pre-blending of the total blend or even partial blending of selective ingredients requires batch control and complete traceability from raw material to final product. Blendhub Powder Blending meets all these requirements through a dedicated portable, flexible, safe, turnkey and also modular solution adapted to your specific needs.

The Blendhub Powder Blending solution applies processes and technology in a modern and efficient way to ensure food safety in all aspects. It further supports new and more flexible business models, benchmarking industry drivers and strategies.

Exhibitor: Bosch Packaging Technology

Exhibitor: Bosch Packaging Technology

Product: SurePOUCH reclosable, flexible pouches

Bosch Packaging Technology’s SurePouch is a reclosable, flexible pouches with a wide range of applications from retail to food service. The packs are filled on the new SurePouch clean-fill machine series (SPC), roll-fed vertical form, fill and seal (VFFS) machines with a small footprint of six square meters. The pouch formats “Retail” for retail sales and “Food Service” range in filling volume sizes from 100 milliliters to five liters.

The SPC can produce four different pouch formats. The formats EZPouch, EZGable and EZSquare, with filling volumes from 100 milliliters to five liters, offer flexible applications for retail. For food service, the EZPillow can hold up to 20 liters, allowing for easy and quick refilling. All formats are produced, filled and sealed with the same machine. This enhances flexibility for the manufacturer since it allows the user to expand the product portfolio without fundamentally converting the production line.

Clean-filled applications for the SurePouch include non-carbonated beverages and water, dairy products, concentrates, soups, sauces and dressings. The SurePouch system is capable of filling viscous liquids up to 25,000 centipoises as well as particulates up to 25 millimeters in diameter while protecting particulate integrity. The machine can also handle dry bulk goods, such as flakes, powders, rice or coffee.

The new vertical form, fill and seal machine is capable of filling a variety of products, achieving hygiene standards up to ultra clean-fill. SurePouch packs are also fitted with reclosable spouts, which are ultrasonically welded to the exterior of the pouch and can be positioned in various locations. They provide an enhanced hygienic feature as the product is filled directly into the pouch and not through the spout. The closure only comes in contact with the product when the consumer opens the package. The spouts are available in sizes of 10, 20 and 30 millimeters. Bosch also provides customized options for food service. Alternatively, drinking straws or simple tear-notches can be added to the SurePouch pack styles. For the food service sector, adjusting extra handles to the upper seam simplifies lifting and dosing when pouring.

In addition to the SPC machine, Bosch supplies both the spouts and the lightweight film or laminate structures for the SurePouch packs, guaranteeing seal and package integrity while ensuring easy handling, storage and dispensing of products. Due to its stable design, the package still stands-up once vacant. Made from flexible materials, it allows high evacuation rates for increased utility as well as collapsibility for efficient disposal. Compared to cartons, metal containers and cans, SurePouch packs are created with thinner gauge and lighter plastic materials, resulting in significant cost and energy savings throughout manufacturing and transportation. In comparison to alternative packaging concepts, SurePouch results in weight reduction of up to 80 percent. The new flexible pack style also helps to lower the product-to-package weight ratio compared to rigid alternatives.

Exhibitor: Tetra Pak

Exhibitor: Tetra Pak

Product: Tetra Lactenso Aseptic with OneStep technology

Tetra Pak showed its Tetra Lactenso Aseptic with OneStep technology, a best-practice line that incorporates UHT white milk production within a single, high-throughput process.

OneStep technology eliminates the need for pasteurization pre-treatment and intermediate storage of raw milk. In one unbroken step, raw milk is preheated, clarified, separated, standardized and homogenized before undergoing UHT treatment and regenerative cooling; it is then transferred to two aseptic buffer tanks. This shortens processing time from as much as two days to just a few hours; cutting operating costs by up to 50% compared with conventional solutions.

In essence, the innovation of OneStep technology is that it combines heat treatment, separation and standardization into a single step, which significantly simplifies and accelerates the production process.

In addition to shortening the time it takes to process raw milk, OneStep technology also incorporates aseptic buffering. This enables completely automated and continuous UHT operations, with fewer process steps and smaller hold-up volumes in the line.

Tetra Lactenso Aseptic with OneStep technology can reduce energy consumption by more than 40%, reduce effluent load by up to 40% and cut water consumption by as much as 60%. These savings are estimated to reduce the carbon footprint of the production process by around 40%. Furthermore, the streamlined process cuts product loss by up to 33% compared to conventional UHT solutions.

With the ability to change the fat content of milk products without stopping production – and to run milk with different fat contents at the same time - OneStep technology provides outstanding aseptic line flexibility, enabling efficient production planning and high utilization of filling machines with up to 100% availability.

Exhibitor: Krones

Product: Single-flow pasteurizer concept for the low output range

For low-output filling of beverage cartons with products containing fruit, Krones developed a single-flow concept as a stand-alone solution in the process technology environment. The chunks of fruit or the fruit preparation are before any thermal product treatment mixed in a tank with juice to form a finished beverage. This is heated up gently in the downstream shell-and-tube heat exchanger system, before being passed to the aseptic filler.

The entire pasteurizer system, featuring a shell-and-tube heat exchanger, plus the media and energy supply equipment, is pre-assembled on a frame, supplemented by a VarioStore aseptic buffer tank, a product de-aerator, and a homogenizer. Thermal product treatment with the VarioAsept J pasteurizer, including a product de-aerator, has proved highly flexible in terms of flow rates and product viscosity. This flexibility is attributable not least to the combination of smooth pipes and the cross-corrugated pipes used by Krones at the shell-and-tube heat exchanger. The fruit chunks can measure up to 10 x 10 x 10 millimeters.

When designing the system, special attention was paid throughout to minimising the shear stresses acting on the product. This has been achieved thanks not least to the use of twin-screw pumps, a very low pressure profile over the entire pasteurizer system, and the elimination of control valves. This thermal product treatment concept opens up entirely new possibilities for first-time users to supply the beverage market with ultra-high-quality fruit-based innovations, while at the same time enabling them to produce even quite small batches with viable cost-efficiency whenever necessary.

Exhibitor: Air Quality Process/Safrair

Products: Ammonia regulator and the ventilated hygrometry sensor

The quality of maturing and surface of certain cheeses (hard cheese) highly depends on the level of ammonia inside the rooms. Air Quality Process has developed a global solution able to

control together temperature, hygrometry conditions and the level of ammonia, fitting its air-conditioners with a triple effect trapper.

The ammonia regulator met two major challenges:

1. Highly hygienically conception. Exchanger with smooth tubes in stainless steel, washable in CIP and controllable in every single point (unique concept patented and having USDA approval), outside water curtain and recovery tank for an immediate visual control of the water quality, motor outside the air flow and air of the room.

2. Important reduction of operating costs. Reduction of the water and electricity consumption up to –50%.

The ventilated hygrometry sensor has a “tube” that ensures a 3 meter/second speed on the damp probe, allowing an unequalled quality of measurement and information for the maturing rooms with high hygrometry (too optimistic with static hygrometry sensors). The final aim is to limit cheese water losses.

Exhibitor: Sidel

Exhibitor: Sidel

Product: Equipment, packaging for aseptic filling

Sensitive products have become the fastest growing area for PET bottles in recent years as a result of consumers’ expectations for more natural, healthy and value-added products. This has led to a rise in demand for aseptic, hot-fill and ultra clean solutions to package juices, nectars, isotonics, teas, liquid dairy products and products with pulps and particles.

Beverage producers need to focus on food safety and simple and efficient packaging solutions to satisfy growing demands, but also on flexible solutions that cater to different packaging formats and types with minimal production downtime and costs.

Unique in aseptic filling

Sidel will unveil a number of pioneering technologies and innovative packaging solutions designed to satisfy the rising demands for healthier drinks while respecting the specifications of those sensitive products. Among them are extensive aseptic capabilities, including the proven dry preforms decontamination technology Predis. Combi Predis/Capdis FMa has been specifically designed for the aseptic blowing, filling and capping of sensitive products in PET bottles and is still unique in aseptic configuration.

The technology also offers unlimited lightweighting possibilities. Sixty Combi Predis systems have already been sold worldwide, equivalent to more than five billion bottles produced with Predis to date, saving 600 million liters of water and around one million liters of chemical agents.

Sidel will also present different hot-fill and aseptic filling technologies, dedicated to beverages with slurry in PET containers, meeting relevant official standards for many types of end products with pulp, fibers, puree, sacs, particles, juices or dairy products.

Exhibitor: Fischer Planning and Beth-El

Product: Ozone sterilization module

Fischer Planning/Beth-El Industries introduced a new ozone sterilization module for cups and bottles that can be integrated into filling/packaging lines, both in new or existing machines. The ozone gas is produced onsite; standard electricity (230 V) is enough to power the gas generator. Each cup will be flushed with filtered oxidant (Ultra Low Penetration Air, 0.3µm), followed by suction cleaning and neutralization of the disinfectant. The unit can likewise sterilize closures. All processes are running fully automated.

Exhibitor: Eagle Product Inspection

Product: Compact x-ray inspection system

Eagle Product Inspection launched the Eagle Pack 240 XE, a cost-effective, compact x-ray inspection system for contaminant detection. Facilitating compliance with international food safety standards and retailer safety guidelines, the system is ideal for small and medium-sized enterprises seeking to export packaged products or expand locally. The Eagle Pack 240 XE operates with Eagle’s SimulTask XE inspection software, which provides on-screen self-diagnostics, product imaging and recording to ensure complete traceability throughout the production line and ease of due diligence.

With a compact design and adjustable height, the Eagle Pack 240 XE is easily deployed into existing production lines, often directly replacing existing metal detection systems, without the need for large amounts of added space or additional infrastructure.The new x-ray inspection system is able to detect and reject foreign body contaminants such as metal, glass, stone, bone, plastics and rubber in packaged products. The machine’s detection sensitivity is uncompromised by packaging type, making it suitable for use with products packed in metalized film, foil, jars, cans and small packages common in the confectionery, bakery, ready meals and dairy sectors.

The Eagle Pack 240 XE is a new addition to Eagle’s portfolio of reliable, versatile and easy-to-use x-ray inspection systems. Other systems in this range have a number of capabilities, including ability to check mass, evaluate compartmentalized fill level and analyze fat content.

Exhibitor: Almatec

Product: Sanitary air-operated double-diaphragm pumps

Almatec BIOCOR Series Pumps, one of Almatec’s key product lines within the food processing industry, have been designed to meet the strict standards, regulations and operational requirements that govern the manufacture of food products because it contains no horizontal areas. The B20 and B32 models utilize ball-lifting magnets that can be attached to the pump housing from the outside at the location of the four ball valves. With the use of magnets, the ball valves can be lifted from their seats, allowing the pump to be drained entirely without needing to be disassembled or removed from the application. This enables clean-in-place (CIP) and sanitize-in-place (SIP) capability.

Almatec BIOCOR Series Pumps, one of Almatec’s key product lines within the food processing industry, have been designed to meet the strict standards, regulations and operational requirements that govern the manufacture of food products because it contains no horizontal areas. The B20 and B32 models utilize ball-lifting magnets that can be attached to the pump housing from the outside at the location of the four ball valves. With the use of magnets, the ball valves can be lifted from their seats, allowing the pump to be drained entirely without needing to be disassembled or removed from the application. This enables clean-in-place (CIP) and sanitize-in-place (SIP) capability.

BIOCOR Series pumps are available in three sizes, B20, B 32 and B 40, with maximum capacities of 15 to 70 gpm (3.5 to 17 m3/h) at a maximum discharge pressure of 100 psi (7 bar). The material for the wetted housing parts is electro-polished 316L stainless steel with a center block of PE conductive. The suction and discharge ports are offered in a clamp sanitary connection for inlet/outlet, but are available in a variety of sanitary threads, while the diaphragms, ball valves and O-rings are made of PTFE or EPDM. BIOCOR pumps are equipped with the patented PERSWING P air-control system, which ensures accurate reversal of the main piston and low noise levels.

In addition, BIOCOR pumps have earned certifications for hygienic design and cleanability from both the 3A and EHEDG organizations, in addition to material compliance as stipulated by the FDA.

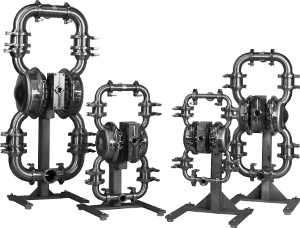

Exhibitor: Wilden

Exhibitor: Wilden

Product: Stainless steel AODD pumps

Wilden’s Pro-Flo X HS (Hygienic Series) stainless steel line of AODD pumps has been designed specifically to deliver the sanitary performance that is necessary in a wide variety of food and beverage processing operations. Offering the versatility, safety and capability needed in food and beverage processing, The Pro-Flo X HS efficiently pumps a full range of viscosities, solids and shear-sensitive products.

The design of HS pumps do not contain any mechanical seals or rotating parts, which eliminates any nooks and crannies where product residue can be trapped and compromise the sanitary operation of the pump. These pumps have also been engineered to meet the highest sanitary standards and requirements in the food and beverage processing industry, including those by EHEDG, 3A, CE, ATEX. USP Class VI and FDA CFR 21.177.

Pro-Flo X HS pumps also feature Wilden’s patented Pro-Flo X air-distribution system (ADS) that allows the user to control air consumption and flow rates with the turn of a dial, resulting in reduced energy usage and true cost savings.

In addition to its Pro-Flo X HS pumps, Wilden Saniflo Vacuum-Controlled (VC) Series Metal Pumps and Saniflo Drum Unloader System (DUS) have also been designed with food and beverage processing applications in mind. Wilden VC pumps have been designed to efficiently and sanitarily handle a wide array of very large solids because they do not employ an air motor, but utilize a vacuum generator that draws the product into the wetted housing. The Saniflo DUS has been designed to hygienically handle highly viscous food products that need to be transferred from storage barrels into mixing tanks during the manufacturing process.

Exhibitor: Mouvex

Exhibitor: Mouvex

Product: Eccentric disc pumps

Ideal for fluid-handling applications within the food processing industry, Mouvex SLC-Series Eccentric Disc pumps are designed to deliver superior volumetric efficiencies. With higher volumetric efficiency, SLC-Series pumps are capable of handling thin, abrasive, aggressive and higher viscosity fluids while increasing productivity gains and energy savings. Other design benefits of the SLC-Series include seal-less construction; low shear and agitation of the pumped product; the capability of handling solids and abrasives; self-priming; line stripping; and the ability to run dry. SLC-Series pumps also feature CIP cleaning, SIP sterilization, and include versions with both 3A and EHEDG certifications.

In addition to its SLC-Series, Mouvex C-Series and Micro C-Series Eccentric Disc pump lines to provide a wide array of unique pumping technologies for food processing applications. Eccentric Disc pump technology is quickly becoming well known in food applications as the “problem solver” by delivering the performance of traditional positive displacement pumps, while creating a constant flow that is independent of both pressure and viscosity. Constructed with a seal-less design, these pumps offer the food industry the most reliable prevention against leaks and product loss.